The Secret Race to Save a New York Skyscraper From Collapse

- Youtube Views 0 VIDEO VIEWS

Video narrated and hosted by Fred Mills. This video contains paid promotion for AMD Ryzen™ Threadripper™.

IN 1978 NEW YORK came close to complete and utter disaster.

Citicorp Tower was once one of the tallest buildings in New York when it was completed in 1977. For years it had a terrible secret… an engineering flaw meant that with the right gust of wind, it could have completely fallen over.

It’s July 1978 and under the cover of darkness construction teams are working nonstop all through the night to secretly reinforce this skyscraper.

There is a hurricane on the way that if it makes landfall, could topple this building and completely blow it over.

“It wouldn't collapse, it would topple left or right. And it would take, it could be a domino effect. It could collapse into other buildings, which could in turn collapse into further buildings. And it could have been an absolute nightmare,” Michael Greenburg, Author of The Great Miscalculation: The Race to Save New York City's Citicorp Tower tells us.

Emergency responders are on stand-by to evacuate the ten blocks surrounding the skyscraper and three different weather services are employed to monitor the winds 24/7 in case of any sudden changes.

Winds strong enough to topple this building blow through New York City once every sixteen years - if they were to hit this skyscraper on one of its corners it would fall and not just flatten everything around it but potentially create a chain reaction, toppling skyscraper after skyscraper.

In one of the densest cities in the world, the human cost, the damage, would be unimaginable.

And nobody in the city knows about this. Not even the people who go to work in the tower every day. No one except for the bank that owns the building, the construction welders, emergency responders and the structural engineer behind the tower.

This is the story of the secret race to stop one of New York’s tallest skyscrapers from collapsing.

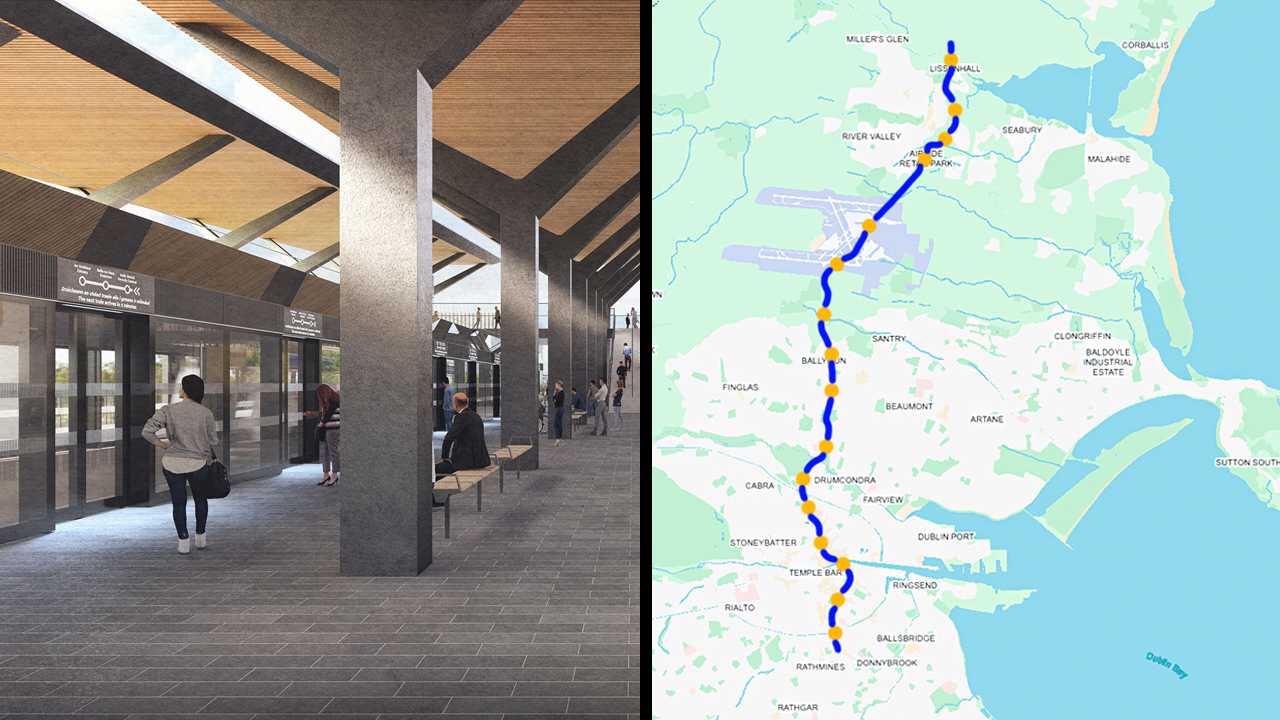

Why build a skyscraper on stilts

So how on earth could one of the tallest buildings in the world at the time have such a fatal flaw in its engineering that once every 16 years strong winds could knock it over?

Looking at Citicorp Center - later renamed the Citigroup Center or simply 601 Lexington - it’s not particularly evident why it would have such a structural flaw. In fact, it looks like a pretty ordinary building with an angled crown to help distinguish it from New York’s other Goliaths.

It’s when we come to street level that we find one of the most bizarre skyscraper bases in history.

Above: The skyscraper's unusual stilts.

Citigroup Tower is built on enormous stilts. This isn’t an aesthetic choice, although it is quite incredible to walk underneath.

“The building attracted a lot of attention when it was under construction in the late 70s, in part because there had been both nationwide and here in New York, there had been a bad recession. And when there are no big new buildings built in New York for a few years, everybody starts getting a little itchy because that's what we do, is we build,” Donald Friedman, Associate Member of the ICE and Fellow of the American Society of Civil Engineers tells us.

“There was a lot of... strife in the city at the time,” adds Greenburg.

“It was a time where a lot of businesses were fleeing and Citicorp, through its chairman, Walter Wriston, had made the decision that they were going to remain in the city, invest in the city.”

Citicorp’s CEO Walter Wriston was a fearsome businessman, what he said went.

So the company went about purchasing several properties in Manhattan so they could own an entire block to build their new headquarters.

“They were successful over time. It took years to do it, except for the church, St. Peter's Church at the corner of East 54th and Lexington,” explains Greenburg.

There was, what the Chinese would call, a stubborn nail in Wriston’s plans. A church that would only allow the sale of the land to go ahead under one condition.

“The pastor of that church was a really forward thinking, Harvard educated pastor by the name of Ralph Peterson,” says Greenburg. “And Peterson was, he was shrewd. He understood the value of his corner and he knew that whoever was going to construct anything on that lot or on that block was going to need him.

“They ultimately worked a deal with the bank where they would get a brand new church building. but it had to be in the exact same spot.”

Watchon would have his skyscraper but it would have to be built up and over a new St. Peter’s Lutheran Church.

Citigroup could build their new headquarters anywhere around the church, including airspace above it. They chose all of the above. They would build their skyscraper on stilts.

But, the location of the church meant that these stilts would not be able to be placed under the corner of each building, which would be the safest and strongest place to do so. If they did that, one of them would pierce through the new church.

The architect of Citicorp Center Hugh Stubbins, knew he would need one hell of a structural engineer so he turned to his friend William LeMessurier.

“He was known for his quick wit, academic prowess,unbelievable intellect, endearingly eccentric, compulsively detailed, and also extremely creative. And he had done some projects, such as the Boston City Hall, which is now affectionately known as the ugliest building on the face of the Earth,” explains Greenburg.

“The Citycorp Tower, I think, was the first major skyscraper, certainly in New York, that he had done. And after completion of that building, his career catapulted.”

As the story goes, they met for lunch at a Greek restaurant and LeMessurier took out a napkin and sketched the building, with the stilts in the middle of the facade.

How to engineer an impossible building

The unusual placing of the columns in the middle rather than on each corner meant the skyscraper would face significant engineering challenges.

These challenges would have to be solved using what we today might regard as rather primitive techniques.

Above: New York in the 1970s was a very different place.

“The 70s is a sort of a transition era for structural engineering. Mini computers were available to do frame analysis, but they were expensive and slow,” Friedman tells us.

“What you have to keep in mind is that, you know, very large buildings up until the 50s were done entirely by hand calculation using relatively very primitive analysis methods.

“The way the building was analyzed was not how it would have been analyzed 10 years earlier, and it was not how it would have been analyzed 10 years later. It was a time when things are changing very rapidly. And the building was analyzed using two two-dimensional analyzes, one for wind blowing north-south, and one for wind blowing east-west.”

LeMessurier would have to create a series of complicated engineering solutions to compensate for the stilts being in the middle of the facade. Normally the corners of a skyscraper are the strongest part of the building, but that would not be the case here.

To address this, the tower was equipped with a system of chevron-shaped braces inside, which redistributed the building's weight.

All of the weight of the building would have to be redirected towards the middle using triangle shaped braces.

“The system was really a set of structurally independent V-shaped chevrons, each of them eight stories in height and intersected by massed columns vertically extending the entire length of the building. And the purpose of this was to basically gather the wind stresses against the building and channel them down through the mass columns down to the bottom truss and into the centrally placed legs at the bottom of the tower. It was ingenious. It hadn't been done often before,” explains Greenburg.

“Something that may not be obvious to a lot of people, gravity load is not the problem in a very tall building. Lateral load, wind load, or seismic load is where all the effort goes,” adds Friedman.

The weight of the building would also have to be significantly lighter than that of other skyscrapers to accommodate this type of structural engineering.

This made the skyscraper susceptible to strong winds. To stop the building from swaying too much a tuned mass damper was installed at the building’s crown.

This fully automatic "tuned mass damper" would counteract any unintentional movements of the high-rise building. It was unprecedented in New York.

This would stop the building from swaying in the wind and creating… discomfort for those inside.

“In general, they're not used for structural safety,” Friedman tells us. “In other words, you don't count on the tuned mass damper to keep your building from falling over. What they're used for is to reduce the motion because that's what people perceive and people get very upset when there's noticeable motion in a tall building.”

“The officers at Citicorp at first were a bit concerned about the public relations aspect of putting this block of concrete at the top of the building to stop what? Building movement, building, you mean, people could get like viscerally sick, you know, from building movement?” adds Greenburg.

Of course, tuned mass dampers are now incredibly common in skyscrapers. The most famous one in Taipei 101 is even displayed for the public to view. You now practically can’t build a highrise in New York without one.

A student named Diane

LeMessurier had done the impossible and solved the engineering challenges associated with the centre stilts.

The skyscraper rose on the New York skyline and opened in 1977 as the seventh tallest building in the world. By all accounts it was a great success. LeMessurier even toured the country giving lectures on his engineering ingenuity.

Above: The building changed the New York skyline.

“Everyone knew, even when the building was being constructed, that this was something special. This was something new and interesting on the skyline,” says Greenburg.

But, barely a year later, a university student using the building as a case study found a terrifying problem with the design.

“It seemed to have... a lot of aspects that would make for a very interesting thesis,” Diane Hartley tells us.

In the 70s Hartley was a student at Princeton University and she was writing her thesis on tall buildings.

“There lot of technical complexities, structural complexities that made it robust enough to do an engineering analysis. So I wrote up some thoughts and approached David Billington and he agreed to take me on as an advisor. He was concerned because the building was already standing that I might need to delve a little deeper.

“The engineering team in New York City had been very kind and generous to me when I had approached them.

“I wound up taking a bus or a train up to New York and spent a day with the engineers. They were very gracious. We talked in their offices and they sent me back to school with a complete set of engineering drawings and calculations for the project.”

Citicorp and the engineering team were at first so enthusiastic of Diane’s thesis they offered her $10,000 to turn it into a coffee table book once she had finished it.

“They were interested in leveraging the work I was doing on the thesis, which was a pretty significant homage to that building. And they thought it would fit nicely into their PR plans.

“I had left some of what I considered the easier analyzes to the end.

“So I was wrapping it up and went to do the wind analysis, looked at the primary wind analysis and then the quartering wind analysis.

“When it came time to double check the quartering wind analysis, which I had determined would yield a 42% higher loading. I didn't see those calculations.”

LeMessurier had taken into account the winds that act perpendicular to the skyscraper, but neglected the quartering winds that would hit the building on its corners.

The corners of skyscrapers are typically the strongest part of the building, but, of course, the corners of this building aren’t attached to anything on the ground. They float above it.

“So I assumed I was missing something. So I do remember making a call back to the office, uh, probably. A week or two before my final deadline. And I believe our exchange was captured in our thesis. It didn't quite make sense to me, but at the time, given my status as a student, the fact that I was not sleeping a lot, trying to burn the midnight oil, getting things done, I essentially just took his words verbatim.

“I remember being frustrated because I assumed I'd made a mistake and it didn't make sense to me. But neither did I feel I had put my finger on something that was any sort of an issue.

“However, when I got my comments back from my thesis advisor, David Billington, he clearly put his finger on that and said, no, this is not quite right, but here we were, the academic course year was over and everyone moved on.

“Obviously if any one of us had thought it was very, very critical. We would have done something else and not just let it go.”

“She's certainly not in over her head because the final result was breathtaking,” explains Greenburg. “She produced a 460 page a double-volume leather-bound thesis with 440 end notes. It was a treatise, and it was a complete study of the cultural, political, and structural ramifications of the Citicorp Tower.”

As for that $10,000 coffee table book?

“Alas, they never returned my call,” reveals Hartly. “And after about two or three months, I gave up and went and got a real job.”

Who was Diane Hartley to argue with these highly accomplished engineers? So she drops it and assumes she was the one who made a mistake.

LeMessurier, interrupted

“At the same time, another student in New Jersey, an architectural student by the name of Lee DeCarolis,” Greenburg tells us. “He's an undergraduate also, he's a freshman. He knows nothing. Other than his professor has said to him, you need to write a paper and you could probably write a good paper about the Citycorp Tower.”

This student reaches similar conclusions, thanks to help from his professor. He reaches out to the engineering team for Citigroup Tower and actually gets through to LeMessurier.

“He's in a meeting and he gets interrupted by his secretary. She says, there's a student on the phone, says, you know, says his professor says that the columns on the CityCorp tower were placed in the wrong location. And LeMessurier bristles, you know, because he's an academic, he's a professor. His curiosity peaks. So he leaves the room and he takes the call.”

Above: Nobody knew of the building's dangerous engineering crisis.

LeMessurier dismisses this second student's claims, much like his engineering team dismissed Diane Hartley. And the matter is closed.

Except, LeMessurier now has a nagging feeling of dread… Did he miscalculate the engineering?

“He starts doing some notes and taking some notes and preparing some calculations and he starts realizing as he's doing the calculations that it's what he called some very peculiar behavior,” explains Greenburg.

He ran the calculations again and had the shock of his life.

Instead of decreasing under quartering wind loads, the calculated load on the steel beams increased by 40 percent.

This is bad enough. But it gets worse. To save money, the beams were not welded and were connected with cheap bolts.

LeMessurier only learnt of this after the fact.

“The engineer says, Bill, didn't you know? We bolted those. We didn't weld them. We were offered a, or the owner, was offered a $200,000 reduction in price if they went with bolts rather than full penetration welds.”

So there were two issues with the skyscraper.

“Usually when you have a problem of this magnitude, it's not from one cause. There are multiple things added together that lead to that problem,” Friedman explains.

“The first issue is the legs being on the middle of each side and the effect that that has on the wind analysis. If it was just that issue there wouldn't have been any need for reinforcing.

And the second issue was that these bolts in the bracing system were not welded down. And they were not welded down because nobody knew about this first issue.

“The bolted connections were not as strong as the welded connections, but they were still stronger than the analysis showed was necessary, and therefore there was no reason not to switch to bolts.”

In the case of quartering wind, the load of the connections would increase by 160 percent. LeMessurier now realised these bolts would not be enough to hold.

A storm like this would also likely cause a citywide blackout, which was common at the time, like the infamous blackout of 1977 which lasted 25 hours. This would also render the tuned mass damper completely ineffective. Not that the damper would be much use anyway.

A storm with winds this strong hits New York on average once every 16 years. That means every year there was a 1 in 16 chance the world’s seventh tallest building could flatten everything around it.

Oh, and they came to this realization just as the city was in hurricane season - when winds like this were expected.

The oncoming storm

It cannot be overstated how much of a disaster this was. And how much worse it could get.

“At that point, (LeMessurier) is faced with the ultimate dilemma,” Greenburg tells us. “He is convinced it will destroy his career if he discloses. He's also convinced if he doesn't disclose, thousands of lives are potentially at risk. And therein is the ethical problem that he's confronting.”

LeMessurier later stated that he wavered between suicide and silence. He knew that if this got out not only would his career be over but there would be mass panic in the city.

“He contemplated suicide. He thought on the way home from Maine, what if I just drove my car into an abutment? I end it all. I don't have to deal with this. I mean, he realized that that was the coward's way out. He didn't want his children to reflect on him in that light. And so he decided really in an epiphany that disclosure was the only course of action. And he described really having a weight lifted off of him when he reached that conclusion, there really was no other possibility.”

It was at that point LeMessurier realised… he had insurance. So he calls a meeting.

“He has to now disclose to this room full of insurance people and lawyers that despite outward appearances, there's a problem with the building and here's why, and here's what it is.”

They tell him he absolutely has to tell the bank.

To LeMessurier’s surprise Citicorp’s CEO Walter Wriston remained calm at these revelations.

They would just have to fix it. Quickly.

LeMessurier worked with the Citicorp higher-up to organise emergency repairs on the building.

Leslie Robertson, who engineered the Twin Towers, was called in to assist LeMessurier with a solution.

“The actual physical fix was pretty straightforward. If you reinforce the connections in the braces, those spliced connections, and make them strong enough for the actual forces, then the problem is solved,” Friedman tells us.

“So the fix was to open up the gypsum board, weld plates onto the braces to reinforce the splices, and then put the gypsum board back.”

LeMessurier and Roberts proposed welding 2-inch steel plates over 200 bolt connections of the column system.

Construction workers welded throughout the night stopping at daybreak - just as the building’s occupants came to work. The repairs were kept top secret, not even those who went to work every day in the building knew about them.

Citicorp’s CEO Walter Wriston, as well as the emergency responders, agreed not to let the public know. That would create panic.

“The building department was involved with this,” says Friedman. “And they made the decision that there was no need to evacuate everybody around the building unless there was evidence of a direct hit coming. And the nice thing about hurricanes is you do know a few days in advance. So it would be plenty of time.”

Above: The evacuation zone was a radius made of several blocks around the tower.

Carpenters appeared every afternoon at 5 p.m., erecting wooden sheds around the beams. When they finished their work around 8 p.m., the offices in the Citicorp Center were empty – but it didn't stay that way for long.

In the greatest possible secrecy, teams of welders came. They tore open the wall coverings and concentrated on the steel plates. For eight hours, they worked to reinforce the columns, until several clean-up teams came by at 4 a.m. By the time the first office staff arrived around 8 a.m., it looked as if nothing had happened.

The NYPD worked out an evacuation plan spanning a 10 block radius. 2,500 Red Cross volunteers were on standby, and three different weather services were employed 24/7 to keep an eye on potential windstorms.

“Remember, a collapse of a high-rise building is seared into our minds tragically, as a building that simply falls into itself. In the case of the CityCorp Tower, the concern was that if one of the splices fractured,” Greenburg tells us.

“They were all going to break and the building would topple, it wouldn't collapse, it would topple left or right. And it could be a domino effect. It could collapse into other buildings, which could in turn collapse into further buildings. And it could have been an absolute nightmare. So yes, they enlisted the help of the Red Cross, local government, local and state government, first responders, and they developed an evacuation plan.

“But they did the evacuation plan quietly. They said they were canvassing the neighborhood for some type of survey because they wanted to know and needed to know how many people could be potentially affected by a problem with this building. And so the question became, when do these evacuation plans go into effect?”

“There are a lot of smaller buildings nearby. And as we found out with the World Trade Center, when a large building falls from a large height, it wipes out everything it hits,” adds Friedman.

Of course the welding work did not go completely unnoticed. The lights from the welders were noticeable every night. A New York Times reporter even got suspicions and called LeMessurier. But before they could dig too deep the newspapers went on strike and nobody found out.

Things were finally back on track, when on August 31st a massive storm moving towards New York was given hurricane status.

“Hurricane Ella, began heading for the East Coast, began veering northward. And that's when LeMessur said we were sweating blood. And they were,” explains Greenburg.

Hurricane Ella was reaching speeds of up to 137 miles an hour making it the strongest hurricane ever recorded on Canadian waters.

The welders had to act fast.

The work could not be done in time for when the hurricane was predicted to make landfall. This was it.

Citigroup, LeMessurier and the city’s emergency responders prepared to make a public statement and evacuate the surrounding blocks. They would undoubtedly face backlash for keeping this a secret for a full month. The damage to the city would be in the millions.

But at the eleventh hour the hurricane dissipated and did not reach New York. The city wasn’t notified and this disastrous secret was kept.

The welders finished their work twelve days later and no one was the wiser.

17 years later

LeMessurier is at a dinner party. Life is good, his legacy and career remain intact. Citigroup Center is a distant and resolved drama.

The authorities and Citigroup agreed to mutual confidentiality and that suited everybody just fine.

Feeling comfortable and after one too many drinks at this party, LeMessurier started to tell a friend about the story. And who happened to overhear it? Joe Morgenstern, a writer for the New Yorker.

“And he checked out the story, and he learned it was true,” Greenburg tells us. “So he started making phone calls, and he got a contract, an assignment, with New Yorker magazine to write a piece. that he called the 59 story crisis about the Citicorp engineering crisis. And he contacted LeMessur and LeMessur said, I've been waiting 15 years for this phone call, you know, they kind of on the one, in the one sense dreading it, but on the other, in the other sense, happy to have it because now the story could be told, the building was safe, and LeMessur was able to freely and openly tell his story.”

The story became public in 1995 when it was published in the New Yorker.

“It's funny, I read it while waiting in my dentist's office, he had the New Yorker in the waiting room, and about a week later, everybody started talking about it,” says Friedman.

“What's interesting is it caused a lot of discussion among engineers but not so much among the general public. I was surprised at how little public discussion there was of this. In part because it was already an 18 year old issue. It was solved.”

“After 1995, there was a lot of writing in the technical fields and in the trades about what are the obligations of structural professionals,” explains Greenburg. “And almost uniformly, LeMessurier was praised, and he should be, for his actions here. But there were some grumblings as well that they should have been more forthright. Other engineers could have benefited from the information. If you work in this building, wouldn't you have wanted to know that there was a flaw in this building? At least you would have been given a choice on whether you wanted to be on this high rise with a structural flaw. So there was definitely some debate and there was some criticism.”

Apart from being news to the rest of the world, it was also news to the very person who discovered this engineering blunder: Diane Hartley.

“I didn't really spend too much time thinking about the building or my thesis for that matter,” she tells us.

“In fact, I didn't see the New Yorker article in 1995.

“It really wasn't until. I was, I think it was about 1996, there had been a… televised show about the program. And I remember vividly, I was upstairs with my younger son who would have been about a year or a year and a half.

“And my husband… was watching the show and he started yelling upstairs, honey, honey, your thesis building is on TV. And so I went to our bedroom, turned on the television just in time to see the description of the problem that was discovered and the fact that it was an engineering student… so I was... Shocked. I was just shocked and nearly dropped my son, who by the way works for Citicorp currently, which is sort of this wonderful irony.

“At the time I said, wow, you know, I had my finger on this.”

“She's so modest, and, and humble about all of this,” Greenburg tells us.

“She's you know, named as, you know, the savior of New York City and all these accolades falling on her, and she's confused about it a little bit.

Citigroup tower now stands safely above the New York skyline and has become one of the most famous engineering case studies.

Today we have wind simulation programs and complex computing software to ensure this would never happen again.

However, it’s startling to think how incredibly close this disaster came to being a reality.

Additional footage and images courtesy of the Dronalist, Martina Wagner.

Try AMD Ryzen™ Threadripper™ by clicking here.

We welcome you sharing our content to inspire others, but please be nice and play by our rules.