The Epic Engineering Behind the World’s Highest Bridge

- Youtube Views 2,083,306 VIDEO VIEWS

Video hosted by Fred Mills. This video contains paid promotion for Brilliant.

HUAJIANG BRIDGE is the highest bridge on the planet.

625 metres above the Huajiang Canyon in China, you’d have to climb to the top of the country’s tallest building to get this far off the ground.

Construction crews faced unstable mountain terrain and powerful winds in the race to open the structure earlier this year.

Not only is it dizzyingly high up but its construction features some of the most impressive bridge engineering we’ve ever seen.

Above: Huajiang Bridge in Guizhou. Courtesy of Glabb.

Why build it?

There’s a reason the phrase ‘no three feet of level ground’ is a saying synonymous with locals in Guizhou.

More than 90% of the province, where Huajiang Canyon Bridge is located, is covered in mountains and hills - it’s also stunningly beautiful.

Described as the 'Switzerland of China', it’s recognised worldwide as a travel hotspot because of its cultural offering and stunning views but that doesn’t mean it’s always been easy to get to.

Historically, Guizhou has been a bit of an isolated island and while accessing it was tricky, moving around it was even harder.

It’s why the Chinese government is spending billions to better connect the province with the rest of the country and the wider world.

In the late nineties China opened Guiyang Longdongbao International Airport and a high-speed rail line and expressways now run through Guizhou and the nation’s mountain mission trudges on.

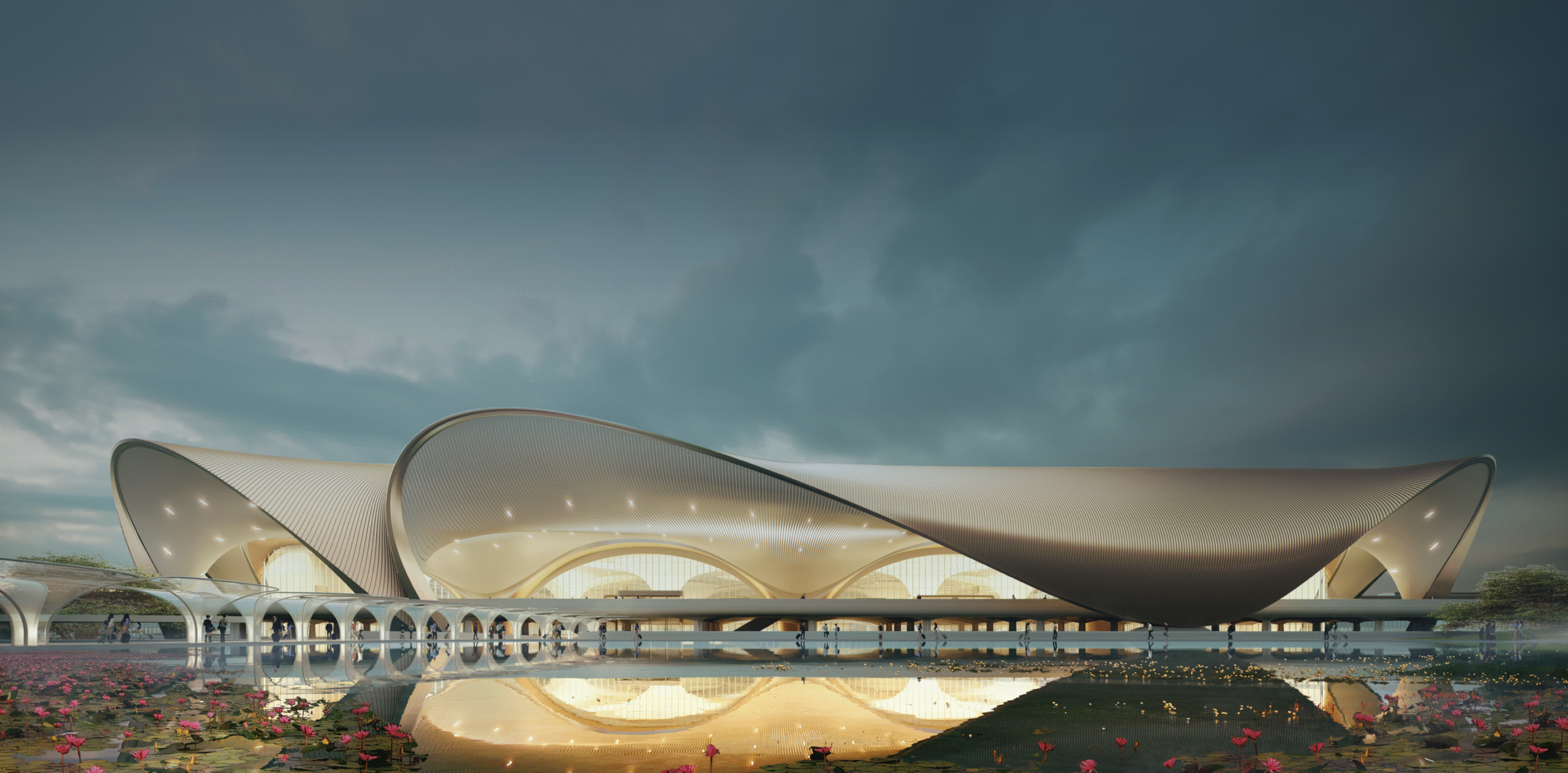

Above: Guiyang Longdongbao International Airport opened in Guizhou in 1997. Courtesy of Gmbsfd.

To enable travel around this mountainous region, Guizhou is now home to 32,000 bridges, providing direct routes through the challenging terrain and the most impressive of all opened earlier this year.

The world's highest bridge

Take a boat ride on the Beipan River and you start to understand the scale of this incredible piece of engineering. Huajiang Bridge stretches across the Huajiang Canyon, hundreds of metres above the ground.

Originally, to get from one side to the other, you’d be driving around winding mountain roads for up to two hours - now, it takes just two minutes.

The bridge forms a key section of the Guizhou S57, a 152 kilometre highway that slices through the heart of a mountain. Using explosives and massive drills, engineers created a v-shaped cut in the rock to cut a mountain in half, allowing for construction of a road through the region.

The expressway connects the Liuzhi Special District and Anlong County via 14 interchanges to make driving there somewhat manageable.

Huajiang Bridge is the giant puzzle piece that connects the highway on both sides of the canyon.

.png?updated=1764180713510)

Above: The Beipan River flows 625m below Huajiang Bridge. Courtesy of Daniel Dumbrill.

Engineers studied the area five to ten kilometres up and downstream to find the right location. That involves a number of considerations like finding the right soil conditions to stabilise the towers, navigating the incredible height of the canyon walls and of course the width of the gap you’re building across.

For the bridge, which stretches 2,890 metres with a main span of 1,420 metres, there were a couple of obvious design options for the architects to consider: cable-stayed or suspension.

A cable-stayed bridge requires very tall towers with cables that come down to support the bridge deck.

The more practical design for long span bridges, and what was agreed for Huajiang, is a steel truss suspension bridge. It’s a well-proven system in rocky, mountainous terrain as the support cables can be anchored into hard rock offering incredible stability.

Before construction could begin, engineers used a virtual pre-assembly technique to map out how the structure would come together - a bit like a practice run.

The steel girder structure consists of 93 truss sections featuring chords and deck panels. Altogether it weighs 22,000 tons - keep in mind that the steel used for the Eiffel Tower weighs 7,300 tons so Huajiang Bridge is three times heavier.

All of that material is being manoeuvred at a ridiculous height and while steel is incredibly sturdy, a 625 metre drop onto rock might just challenge its structural integrity, not to mention the material cost, so accuracy is key.

The biggest crane in the world is Big Carl, a 250 metre piece of kit built by the Belgian company, Sarens.

You’d need three Big Carls stacked on top of each other to hover over the top of this canyon and while you wouldn’t put it past China to go after that record too, they used a rather more intricate solution, as structural engineer and bridge designer, Ian Firth explained:

“What we have here is something called a cable crane which is an overhead system so it’s like an overhead cable runway where the units are delivered to the ends where you’ve already built the abutments and foundations and then you lift it up and it travels along, almost like a monorail. Then you can deliver it to where it needs to be and attach it to the cable system.”

Those girder pieces are placed in the middle and then the bridge is built outwards from there. It's done like this to keep the overall structure balanced, avoiding undue pressure on just a singular support tower.

The steel sections are then slotted correctly into place using the Chinese equivalent to GPS called the BeiDou Navigation Satellite System.

Above: The bridge is built from the middle outwards to avoid pressure on the support towers.

By nature, the canyon has sloped sides which are trickier to build on than a flat surface and given the uneven terrain, configuring structural foundations for even distribution is a real challenge.

It's why the towers are actually different heights - the north tower is 262 metres tall and the south tower is 205 metres in height. The cables are then stabilised using an asymmetrical anchorage design.

“The mountainside is anything but symmetrical", explained Firth. "Your two cables at the back coming down from the tower tops to ground, where the anchorages are, will very often meet the ground at completely different levels or places so the asymmetry will be in the anchorages. Some might be deeper than the others depending again on the local geology and exactly where the cables meet the ground.”

Then we have one of the biggest challenges of all. Whenever you build major infrastructure, the wind is right near the top of the list of challenges to overcome, not least when designing a bridge, especially one standing this high above a big canyon.

The geographic formation of a canyon has a huge influence on wind patterns through something called the Venturi effect, named after the Italian physicist Giovanni Battista Venturi. He observed that when wind passes through a narrow passage, its pressure drops as it increases in speed.

It’s often experienced between tall buildings in cities.

Of course, in a canyon like this one where there are narrow sections where wind gets trapped, its behaviour can be pretty volatile. Gusts are reported to reach staggering speeds, compared to an express train.

A certain amount of testing can be done with a computer but you really need to head to a facility with a wind tunnel. A scaled down model of the bridge and surrounding elements are subjected to recreated wind patterns to see how it performs.

While that might be a familiar concept, you may not have heard of the other system used to prepare Huajiang Bridge: a Doppler LiDAR system.

“Doppler is a system which we know most familiarly from when a siren goes past you, the pitch changes and that’s just the frequency shift when something’s moving. LiDAR is a laser system for representing in three dimensional space surfaces, voids or objects and so what this is doing is using a sort of scatter of laser beams into the air and measuring the frequency shift to the reflected signal", said Firth.

"The signal is reflecting off moisture particles in the air, so what that’s doing is building up a three dimensional image of the moving moisture particles in the sky and that gives you a picture of what the wind is doing.”

It was crucial to account for the geological conditions, seismic events and the wind but just because those conditions were factored into the design, it doesn’t mean monitoring ends upon opening.

As strong as the cables are that support the great weight of the steel, they’re under tons of strain and engineers keep an eye on them by attaching fibre optic strands into the cables themselves.

As the metal wires expand under increased load, the fibre optic strand expands too. Then, by passing light down the fibre optic system, you measure reflections and the extension using a fibre optic strain gauge.

As you can imagine, it’s crucial to keep an eye on the tension - after all, the cables are the most critical aspect of a suspension bridge.

They’re usually formed using preformed parallel wired strands where stacks of wires are bundled together and then collated into one big whole.

More than *just* a bridge

While Huajiang Bridge is a record breaker - and that would usually come with a certain level of acclaim - this is just what China does.

The country has more high-speed rail than anywhere else on the planet, more bridges and a higher number of dams but what’s happening in Guizhou is about more than just setting records.

Since 2012, the nation has been spending hundreds of billions to develop infrastructure projects in its poorest regions.

It’s all part of China’s War on Poverty, to better connect and develop revenue generation outside of the key city hubs like Beijing and Shanghai.

Beyond that, it’s worth pointing out Guizhou is part of China’s Belt and Road initiative, a strategy launched by the nation to create economic corridors around the world. China will be keen to show the rest of the world how developed each area of the Belt and Road route really is.

But that brings us back to why Huajiang Bridge is a whole lot more than it seems - the structure was built with you, me and the rest of the world in mind and like bears to honey, China’s hoping Huajiang will become a tourism trap.

The bridge features an 800 metre glass elevator that takes visitors up to a two storey coffee shop in one of the bridge’s support towers, on the underside of the car deck a glass walkway lets you look down to the canyon (if you dare) and a stunning artificial waterfall spans hundreds of metres across the bridge.

Aside from engineering fans and coffee lovers, China wants Huajiang to become a hub for extreme sports. A bungee jump is attached allowing adrenaline seekers to safely fling themselves from a platform on the world’s highest bridge. Plans are being formulated for professional base jumping events and there’s even talk of a centre for extreme sports below in the canyon.

Huajiang Bridge is an amazing spectacle of modern engineering - it’s testament to the development of this industry that we can construct infrastructure like this in the most inhospitable environments.

Hundreds of millions and even billions of dollars are spent creating travel routes that generate money from visitors far and wide and bridges like the one in Huajiang are literal sightseeing destinations in their own right.

To try everything Brilliant has to offer for free, visit https://brilliant.org/TheB1M/ You’ll also get 20% off an annual premium subscription.

Additional footage and images courtesy of Daniel Dumbrill, China News Service, China TV, China MFA, Shanghai Daily, BBC News, CBC News, Itravell, Xinhua News and China Insider.

We welcome you sharing our content to inspire others, but please be nice and play by our rules.