The World's Tallest Modular Hotel

- Youtube Views 364,048 VIDEO VIEWS

Video hosted by Fred Mills.

IN response to rising construction demand and a severe shortage of skilled labour in the workforce, developers and contractors around the world are now

revisiting the concept of off-site construction, integrating new technologies and manufacturing approaches and embracing it on a scale not seen before.

Emerging as a frontrunner in the hospitality market, hotel giant Marriott is now finalising plans to construct its latest hotel in New York using factory-built modules in just 90 days.

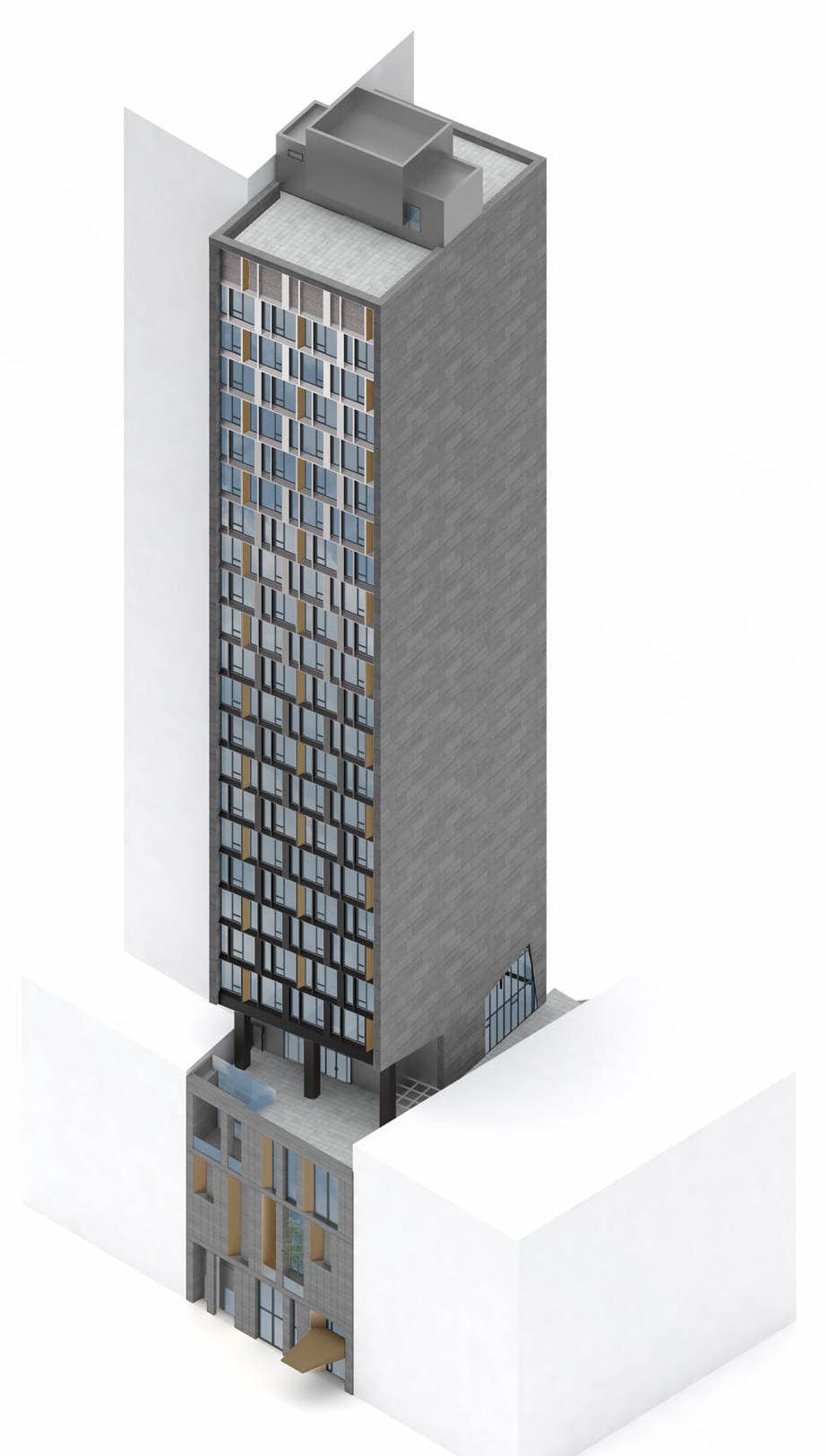

Above: Marriott's AC NoMad Hotel in Manhattan (image courtesy of Danny Forster + Architecture).

Set to stand 26 storeys high, Marriott’s new AC NoMad Hotel will be the tallest prefabricated structure of its kind anywhere the world.

Designed by Danny Forster + Architecture, the hotel uses symmetry to make efficient use of its small Manhattan site, while offsetting the tower to the street in order to create a more dynamic and visually appealing form.

Two key factors drove Marriott’s decision to embrace an off-site, modular construction approach: speed of delivery and cost.

Above: The hotel's facade will be offset to the street to provide a more visually pleasing form (image courtesy of Danny Forster + Architecture).

With high construction demand and a severe shortage of skilled labour in the United States (US) construction sector, Marriott has seen the average build time for its new US hotels rise by 50% since 2011; a factor which significantly impacts revenue when capitalising on new and growing markets.

While comparable structures would typically cost in excess of USD $100 million when built with traditional construction methods, the AC NoMad will cost just USD $70 million to construct, even with the costs of factory manufacture and transportation accounted for.

Additionally, by making use of factory-produced modules, site-specific tasks such as excavation and foundation works can be undertaken concurrently while the structure’s modules are fabricated away from site.

Above: Inside the factory in Poland (image courtesy of DMDModular).

Despite a slightly longer pre-construction design and planning phase, this approach can reduce the on-site build time for a project of this scale by up to six months, while reducing the amount of on-site labour required by nearly 70%.

The AC NoMad’s lobby and lower amenity floors will be constructed on-site using traditional construction methods, however, the hotel rooms themselves will be assembled in Poland before being shipped to the US, ready to install on-site.

Due to their size, the delivery of these modules must be carried out at night when New York’s streets are able to accommodate the oversized loads.

Arriving fully furnished – complete with bedding and toiletries – the modules will be simply lifted from their trucks and positioned on the tower.

With just eight modules required to form a floor, the structure will be able to rise significantly faster than a comparable building constructed with traditional methods.

Above: One of the completed modules ready to be shipped (image courtesy of DMDModular).

While speed and cost were the primary drivers behind Marriott’s use of off-site construction techniques, the approach, in fact, provides a range of benefits.

Constructing the tower’s modules under controlled conditions allows quality to be greatly improved.

This means that – regardless of the weather, changing site environment or the location of each module within the building – every room will be delivered to a consistently high standard.

While the operation of a factory and transportation must all be considered, pre-fabricated approaches can significantly reduce waste in the construction process, limiting the overall environmental impact of new developments.

Above: The completed modules will arrive with furniture and bedding (image courtesy of DMDModular).

In traditional hotel construction, neighbouring rooms often share a single wall. However, factory-built modules typically call for an insulated gap between

each unit resulting in quieter rooms and more enjoyable experience for guests.

Using the AC NoMad – the world’s tallest modular hotel to date – as a starting point, Marriott is planning to construct 25% of their new hotels using prefabricated methods over the next five years.

Additional footage and images courtesy of Hickory, Golden Age, Time + Place, Danny Forster + Architecture Google Maps, and DMDModular. Narrated by Fred Mills.

We welcome you sharing our content to inspire others, but please be nice and play by our rules.