The Race to Replace a Cracked Dam

- Youtube Views 5,462,542 VIDEO VIEWS

Video hosted by Fred Mills. This video contains paid promotion for Masterworks.

HIGH up in the Swiss Alps is one of the world’s most challenging — and epic — construction sites.

Teams here are building an enormous new dam in the most unforgiving of locations.

The site sits 2,000 metres above sea level, hours away from any major city, and you can only reach the place for a few months each year because in the winter it’s virtually shut off due to snow.

This is no ordinary dam, either. It’s going up right in front of another dam, which was built almost a century ago, has a crack and is now damaged beyond repair.

It can’t be fixed, it can’t be demolished, and if nothing is done at all, well, that wouldn’t be good.

But how do you replace something the size of a dam in the middle of a mountain range? And what would really happen if they just didn’t bother? We went to Switzerland to find out.

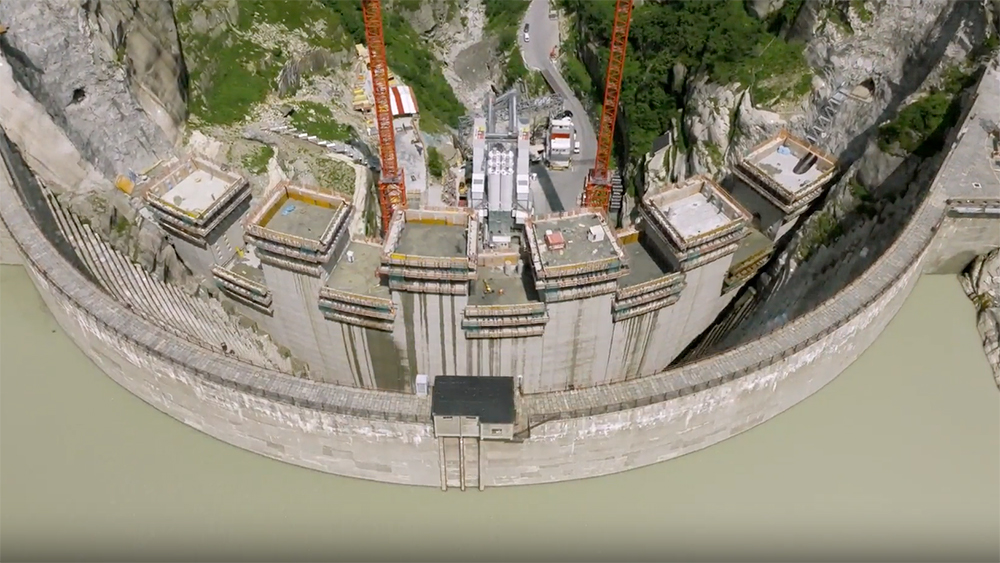

Above: The new Spitallamm Dam under construction in front of the old one.

The Spitallamm Dam is one of two giant manmade walls that were built a long time ago to form a huge body of water called Lake Grimsel.

Why’s it so important? Well, firstly it might not be as famous as that big one in America that it looks very similar to — the Hoover Dam — but this dam does have its own place in history.

Spitallamm is one of the world’s first large arch-gravity dams. It was built up in the mountains between 1925 and 1932 and is actually older than the Hoover Dam, which completed three years later.

At 114 metres, Spitallamm was also one of the tallest dams in the world when it finished. The vast structure was built by some 600 construction workers almost entirely by hand.

But hold on a minute. For those of you wondering what on Earth an arch-gravity dam is, here’s a quick explainer.

It’s where a dam curves upstream and narrows, using its own weight and support bracings to force most of the pressure of the water behind it against the rock walls of the canyon that it sits in.

Above: Arch-gravity dams like Spitallamm are ideal in an area of particularly hard rock and they require less material than similar methods.

The completion of this remarkable structure meant a new artificial lake could be created with water from a nearby glacier, which is then used to make hydroelectric power.

It has a volume of about 94 million cubic metres, making it the largest reservoir owned and operated by energy company KWO, and one of the biggest in Switzerland.

About 30 years after this dam was built though, there was a pretty shocking discovery.

The problem

Back in the ‘60s, when the area was becoming popular with both tourists and filmmakers, some tests were made on the dam which threw up some very worrying results. Investigators found a big old crack on the lake side of the structure.

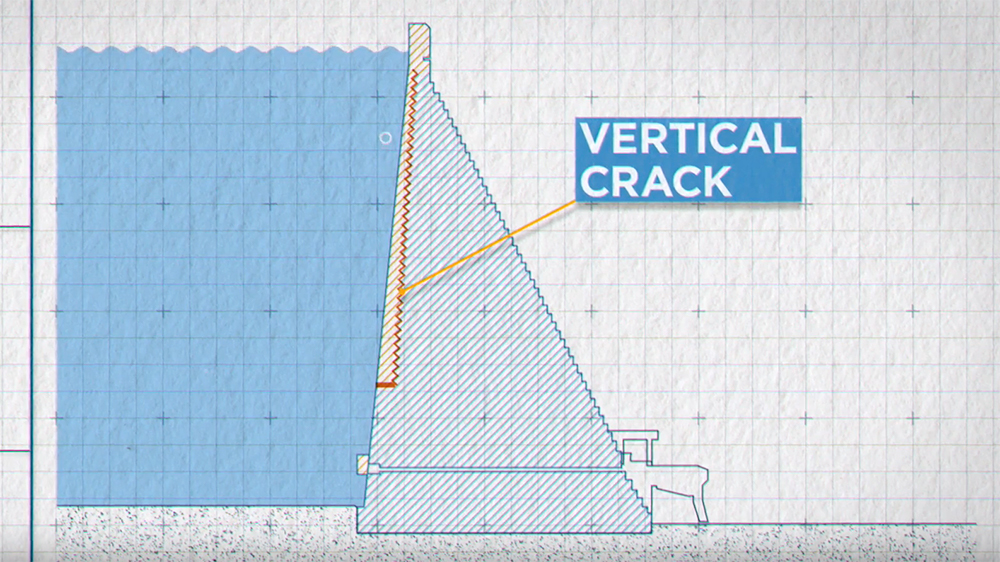

Well, actually it was more than a crack; it’s what’s called a “vertical separation”.

In other words, a massive chunk of material has started to separate from the rest of the dam — the mass concrete. There’s a smaller horizontal crack below the crest of the dam as well.

Above: The vertical separation runs almost all the way from the top to the bottom of the old dam.

Over the years it’s been getting worse and there are concerns about what would happen to the structure in the event of an earthquake.

Yes, Switzerland does get those; in fact, it averages over a thousand every year. They’re usually so small you can’t even feel them, but the one that hit back in 1991, for example, was big enough to damage buildings.

“The worst case [scenario] would be if there is a very severe earthquake in thirty, forty years, when the crack is even bigger. Then it could be that part of the wall falls into the lake, creating a tidal wave, which could affect the valley here,” KWO project manager Benno Schwegler said.

Now at this point you’re probably wondering why you would go through all the effort of building a new dam. Why not just repair the crack somehow or replace the section that’s coming away?

That was the original plan: break off the material that’s already separating and patch it up with some new, better quality concrete so it’s even stronger than before.

But it turned out to be too risky. An investigation showed that doing that could lead to a so-called “alkali aggregate reaction” which could cause long-term damage to the concrete.

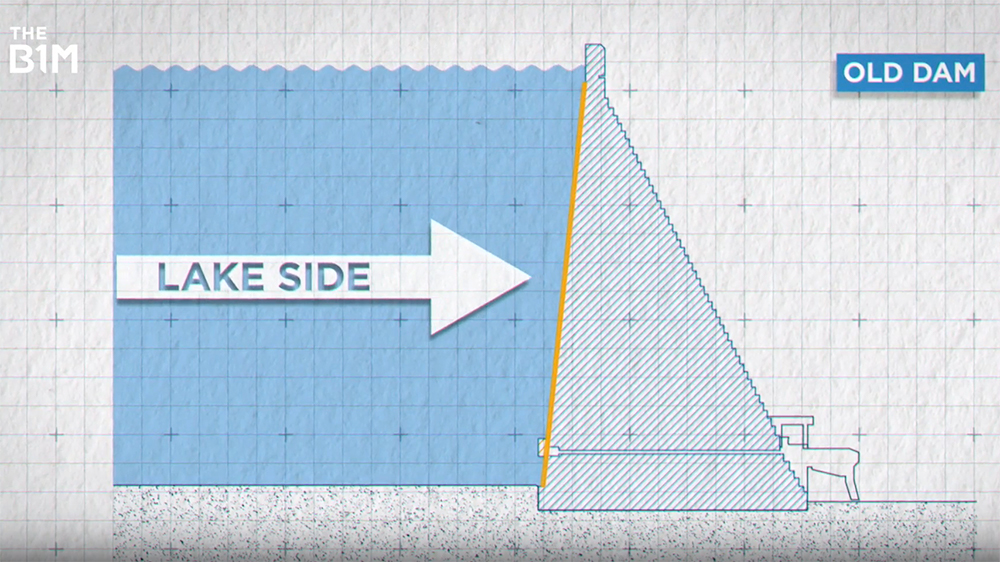

Above: The problem area is on the lake side of the dam.

On top of all this – quite literally – sediment has started building up behind the dam, and is now accumulating around the lower discharge zone.

That’s not good, because if this area gets completely blocked it’ll become harder to release water from the reservoir if they need to.

Right, so what if they just removed it? That would mean all that water having to go somewhere else and because the lake is used to generate hydroelectric power, it would leave a huge hole in the energy grid.

That left them with only one option – build a completely new dam in front of the old one, and flood the area between them.

The original dam will be preserved and won’t be knocked down — it is a piece of history after all — with its replacement taking on the job of absorbing the water pressure. All sounds quite simple when you put it like that, but it certainly isn’t.

The construction process

Cost-wise the USD $140M new dam is pretty small compared to your typical megaproject, but its sheer scale and the challenges facing its teams are immense.

Construction has been underway since 2019, and it’s all set to complete by 2025. What are they doing differently this time? Well, as you can imagine, techniques and materials have come a long way since the 1930s, and the design has changed too.

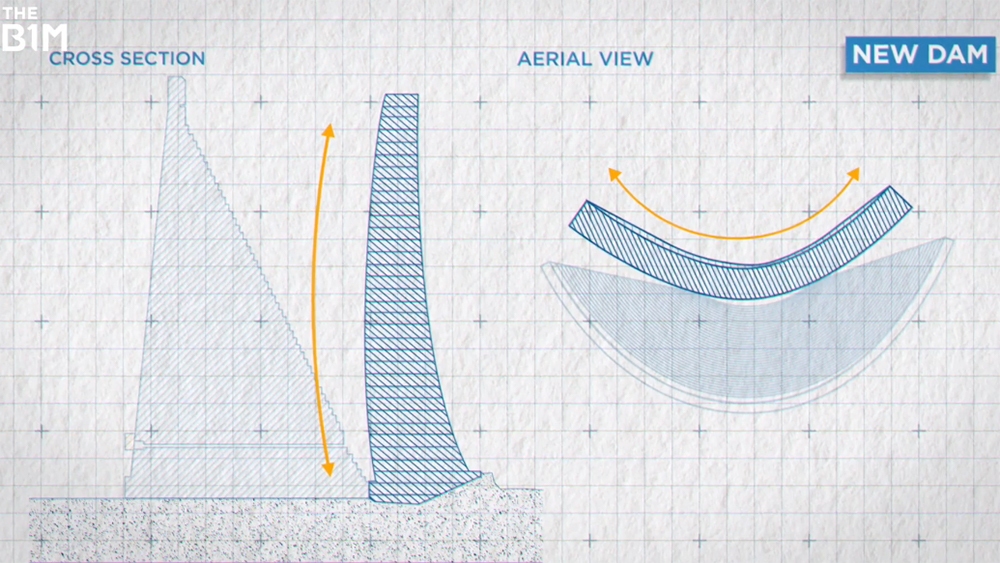

The existing dam was built with a single arch — the huge horizontal curve that can clearly be seen when viewing it from an angle.

But if you look at a cross-section, the lake side of the dam rises up in a straight line.

Its replacement is going to be a double-curvature dam, which means it will curve in a vertical direction too.

Above and below: The single arch of the old dam versus the double curvature design of the new one.

That means that the dam’s walls can be made thinner — meaning less materials — while still having the strength needed to hold back all that water.

The new dam will be the same height as the old dam, but strong enough to be further extended in future if there were ever plans to grow the reservoir.

As for the actual construction, it all started with clearing space for the new dam. This being solid rock, the team used controlled explosives – and doing that right next to the base of the old dam that’s holding back a massive lake full of water without damaging it is just about one of the trickiest construction manoeuvres ever pulled off.

From there the vast dam wall is rising as a series of staggered 15-metre wide towers over the course of four years.

It’s built like that so that each segment can dry – or “cure” – faster and to increase the overall strength of the dam wall.

Above: Overall, some 215,000 cubic metres of concrete will be used.

Next, a huge tunnel is being carved through the mountain. That will allow water to be discharged from the reservoir and sent downstream if the water level ever gets too high.

But before the excavation can be completed, the reservoir must be completely drained by sending all that water down into the hydropower system.

Teams will then clear the sediment on the lake bed and dig the rest of the tunnel before allowing the reservoir to refill naturally.

After that they will gradually flood the area between the two structures and the new dam will take over the task of holding back the weight of the lake.

The old dam can then enjoy its retirement in the same place it’s always been and having finally lost its near century long battle with the lake.

“The most difficult part of this project is that the old wall remains safe and undamaged. The work takes place directly in front of a completely dammed lake during the entire construction phase,” Schwegler explained. “We have to make sure that the wall is stable and safe at all times, even if we are doing blasting work directly in front of it, for example. In everything we do, the wall must remain safe.”

Above: KWO project manager Benno Schwegler standing in front of the new dam

So, there’s a lot of work going on here and a great deal of pressure to get it done fast, and do it right. As you can imagine, one of the biggest tasks is getting all that concrete here, but they’ve found a clever way around that.

An on-site concrete plant has been built just for this project, which uses granite from the construction of the nearby power plant to make the material.

It’s just one example of how the construction process on this project is being shaped by its extraordinary location.

Snowed under

When you’ve got a gigantic dam to build, the going can get tough. The site is having to operate almost continuously — 20 hours a day, seven days a week.

That’s because for about half of the year, this place looks very different to how it does in the summer — when The B1M visited — and all work on the dam has to stop. So, they have to work twice as hard to make up for it.

One person who could tell us what the area is like in the winter is Luzius Gartmann. He’s lived in this region for more than 20 years and is now a tour guide for people visiting the nearby sights, including the dam and the power plant.

“In December there'll be a lot of snow here. Sometimes we have three metres of snow,” Gartmann said. “You know, they stop the construction site mid-October till mid-May. They cannot maintain the construction because of the snow. It's much too cold for work with concrete.”

Above (L-R): Luzius Gartmann talking to The B1M's Fred Mills on a gondola — an essential mode of transport in the winter months.

Basically, when the cold sets in up here you need more than just a thicker pair of socks.

If the project didn’t shut down, those working at height would have to endure 200kph freezing winds, there’s the threat of avalanches, pouring concrete would become next to impossible … none of it sounds good.

Enormous piles of snow aside, there’s the sheer remoteness of it all. The nearest city, Lucerne, is about 50 miles away behind numerous sharply twisting mountain passes, which can make getting the right materials, equipment and people to the site very difficult, even when the sun is shining.

For example, rising high above the site are two massive red cranes with 92-metre-high towers. They had to be transported to site in multiple sections, using 70 lorries.

Above: The lorries had to travel up the winding Grimsel Pass — the only route they could take. Image courtesy of WOLFFKRAN/Daniel Bürki/Grimselfoto.

Because there’s so little space available on site, deliveries had to be made just in time. There could be no delays putting each section in place.

Compared to your average construction project it all feels like a lot of hard work, but like all major infrastructure schemes there’s a bigger pay-off here.

Out of sight – deep below the surface of its reservoir – this dam plays a critical role in keeping the lights on across Switzerland.

That all happens in a turbine room underneath the reservoir – and you have to drive through a two-kilometre tunnel to get there.

Going underground

Once you get through that you come to the power plant Grimsel 2, located 100 metres below the level of Lake Grimsel.

“With all of our 13 power plants we maintain, with 21 turbines and — very important — five pumps, we have the possibility to maintain a perfect balance of consuming and producing electricity in Switzerland,” Gartmann said.

Above: KWO's Grimsel 2 hydro plant is now almost 50 years old.

Grimsel 2 is a great example of a pumped storage power plant. But what does that mean?

In very simple terms, it’s where two or more lakes or reservoirs at different altitudes are connected, allowing water to flow from one to the other. As the water falls at force downhill it turns turbines that generate electricity.

When there’s not a lot of demand for energy, the surplus energy is used to pump water back up to the higher lake. Then, when energy is needed, the water is released again.

Overall, hydropower is a more consistent energy source that doesn’t experience the same peaks and troughs in supply as wind or solar.

KWO has a whole series of systems doing this up in the Swiss Alps, generating energy multiple times from the same water as it flows down from the mountains.

“Water is coming from Lake Oberaar 500 metres above us, and when we are in this power plant running on full power — all the four machines — there are 100,000 litres per second running through these tunnels,” Gartmann revealed.

Just like the Spitallamm Dam above it, Grimsel 2 is another incredible feat of engineering, but amazingly there are some 200 dams across Switzerland and an incredible 700 hydro power stations like this – many of them tucked out of sight, helping quietly power the country.

Above: The B1M's Fred Mills walking on top of the old dam.

Construction projects can sometimes raise questions about whether they’re really necessary, but that’s not the case with the Spitallamm Dam.

As historic as it is, that old dam simply has to make way for a new and improved version.

Yes, Switzerland is pretty unique. Most don’t have the terrain, the climate or the expertise to build and maintain hundreds of dams and hydro plants.

But it’s not a type of infrastructure that’s exclusive to this country and with magnificent structures like these all over the world beginning to age, it might not be the last time drastic action like this has to be taken.

What these amazing teams are pulling off up here – against all odds in this most breathtaking and unforgiving of environments – really speaks to the power of construction and its ability to impact the lives of millions. It looks pretty damn epic too.

This video contains paid promotion for Masterworks. The B1M viewers can skip their waitlist and sign up here.

Additional footage and images courtesy of KWO, Aston Martin, Columbia Pictures, Daniel Bürki/Grimselfoto, Doka GmbH, ETH-Bibliothek, Leo Wehrli, Liebherr, United Artists, Werner Friedli and WOLFFKRAN.

We welcome you sharing our content to inspire others, but please be nice and play by our rules.