The Race to Save Texas’ Failed Megabridge

- Youtube Views 1,665,252 VIDEO VIEWS

Video hosted by Fred Mills. This video contains paid promotion for Masterworks.

They say everything’s bigger in Texas – and that’s definitely the case for the state’s latest megaproject: the new Harbor Bridge.

Stretching 506 metres across Corpus Christi’s ship channel, this will be one of the longest cable-stayed bridges in America, replacing the ageing structure that stands there today.

That is, if it ever gets finished.

Halfway through the project, investigators halted construction after they found a number of safety concerns that, if left untreated, could cause the bridge to collapse.

Now, the project is way over budget and way past its original 2020 deadline, and officials are racing to engineer their way out of this nearly billion dollar problem.

With tens of thousands of people relying on the old Harbor Bridge every day, the pressure is on to fix the new one before it’s too late.

Above: Construction was suspended on the Harbor Bridge twice. Courtesy of Harbor Bridge Project.

Corpus Christi, Texas. Home to one of the largest US ports, this mid-sized city has served as an important gateway into the country for over a century – and over the years, it’s been engineered to adapt as the world changed around it.

To accommodate the rapidly growing oil and gas industries following World War II, the port needed to build a wider passage and a larger bridge for ships to pass through – and so the state took on one of its biggest construction challenges yet: the original Harbor Bridge.

It was an incredible feat of engineering built without the use of modern computers, and when it opened in 1959 the bridge’s massive through-arch structure was so tall that supertankers could enter the port for the first time, igniting further economic growth.

It went on to serve Texas for more than half a century, but was only designed with a 50-year lifespan and as the decades have rolled by the structure has yet again become outdated compared to the size of bridges in today’s ports.

So now, the state is building another new bridge to accommodate larger ships, meet updated safety measures and lower maintenance costs.

Not only will the old bridge be demolished, but over 10km of new bridge and roadways are also being designed and developed.

The new design will be a modern cable–stayed bridge where the road deck is supported by cables connected directly to pylons or towers.

Now, that’s different from a suspension bridge, where the cables spread out across a suspender between the towers.

On the new Harbor Bridge, cables will stretch from the towers to the road deck to carry six lanes of traffic and a shared bicycle and pedestrian path.

The deck will sit an incredible 62 metres above the surface of the water, high enough to clear the massive new ships coming in.

Above: A rendering of the Harbor Bridge. Courtesy of Harbor Bridge Project and Texas Department of Transportation.

Construction started back in 2016 and was due to finish by 2020. But here we are in 2023 with a half-built structure – so what happened?

Well to be perfectly frank, a lot has gone wrong here.

Firstly, work on the bridge has been suspended not once, but twice.

Construction first paused in 2019 following the shocking collapse of a pedestrian bridge in Florida that resulted in several deaths and injuries.

Now, you might be wondering what a bridge all the way over in Florida has to do with this one in Texas.

Well, the collapse was due to an error in its initial design by Figg Bridge Group – the same engineers then working on the new Harbor Bridge.

Investigators looked into the Texas Bridge designs, and ultimately removed Figg from the project, replacing it with new firms.

Construction then finally restarted in 2021.

But not long after the bridge began taking shape an independent study conducted by a third party group found there were still five key safety concerns that could lead to a collapse.

Construction on the main span was halted again in 2022 and the project’s budget grew from around $800M to nearly $1BN.

Here’s what exactly went wrong, and how they’re fixing it.

The first issue is with the foundation system.

The north and south towers of the bridge sit on top of a giant concrete slab the size of two basketball courts. Underneath each of them is a series of 64-metre drilled shafts filled with concrete and steel to transfer the weight of the bridge above down onto solid ground.

But the investigation found that under certain conditions, like high winds, the shafts might not support the weight of the pylons and could sink into the ground.

To address this, the team is extending the foundations and adding more drilled shafts below each tower, enabling them to hold more weight without sinking.

The second issue has to do with the on each of the towers.

These sit on top of a group of piles in order to equally distribute the weight to all the elements underneath. Think of it like a handful of straws when you grip them close together.

The fix here is to create more space underground so the piles don’t bend and slip out of place above the concrete. The piles will be moved deeper underground, which will be supported by the newly drilled shafts from the first solution.

The investigation found that the demand on the piles greatly exceeded their loading capacity, which ultimately could have led to the bridge’s collapse.

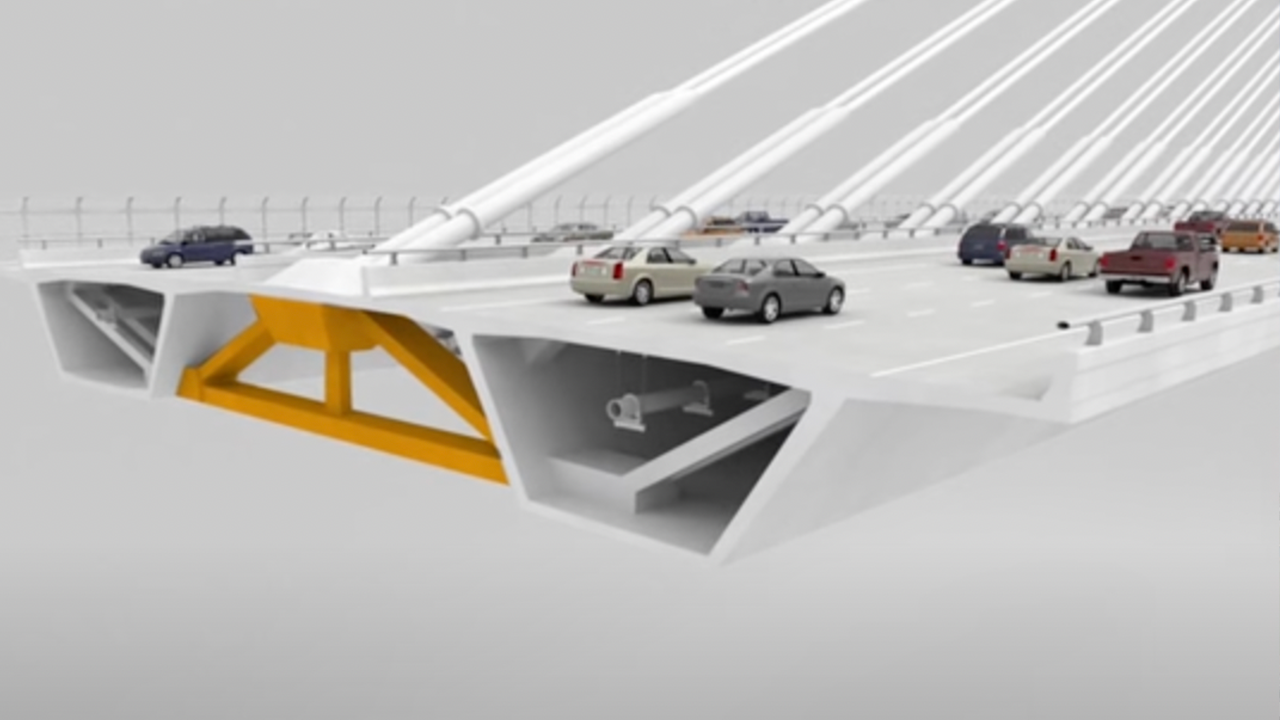

The third problem has to do with the delta frame design – a critical element in a cable-stayed bridge.

Above: The delta frame design element on the bridge. Courtesy of Harbor Bridge Project and Texas Department of Transportation.

This part bears and transfers the weight of the structure onto the cables. A bit like a mast on a ship. Building code requires this project to use non-compressed steel throughout the delta frame in order to strengthen it.

But the investigation found that the Harbor Bridge design didn’t have the necessary reinforcement, putting the structure at risk of cracking.

To strengthen the connections, engineers are roughening the concrete surfaces and adding rebar that crosses the interface.

The fourth problem was something called uplift occurring at two of the piers. This means that instead of the weight transferring down into the cables near the towers, it was causing the structure to raise up.

This occurs when forces like wind or soil move and lift up a structure and its foundation.

And with the bridge’s current design, the bearings aren’t capable of controlling this movement if uplift occurs. This could ultimately loosen the connections and cause other maintenance issues.

So engineers have added rebar to the last two segments on both ends of the bridge. They also made modifications to some of these external bearings to prevent decompression.

The fifth and final issue was caused by placement of the cranes during construction of the main span.

The way the equipment was set up during construction exposed it to high winds, which could cause parts of the incomplete bridge deck to twist.

Now, workers are adding counterweights to balance out any potential movement from the weather.

In April of 2023, yet another issue emerged when one of these cranes caught fire, injuring two workers as debris fell below. The cause of the flames is currently being investigated.

We reached out to the companies involved, but they declined to comment.

The work to fix the new Harbor Bridge is only just beginning to start, but as the original structure continues to age it’s important to get this one right, and quickly.

Construction projects like this are a high-wire act and the race to fix the Texas Harbor Bridge is a powerful reminder of the trust we put in this industry.

Infrastructure has the power to shape millions of peoples lives for the better, but only if it’s built right.

Additional footage and images courtesy of Harbor Bridge Project, Third Coast Drone, Texas Department of Transportation, ABC News and CNN.

We welcome you sharing our content to inspire others, but please be nice and play by our rules.