This Pavilion was Printed with Gravel and Twine

- Youtube Views 2,773 VIDEO VIEWS

IN a rather low tech twist to cutting-edge engineering, Swiss researchers have 3D printed a pavilion in the city of Winterthur using twine and loose rocks.

The video above shows the technique as demonstrated at the Ars Electronica festival earlier this year.

Unveiled last week as part of the Gewerbemuseum Winterthur exhibition "Hello, Robot: Between Human and Machine", the current pavilion was built by architects and engineers from ETH Zurich’s Gramazio Kohler Research unit, which specialises in computational design and robotic fabrication.

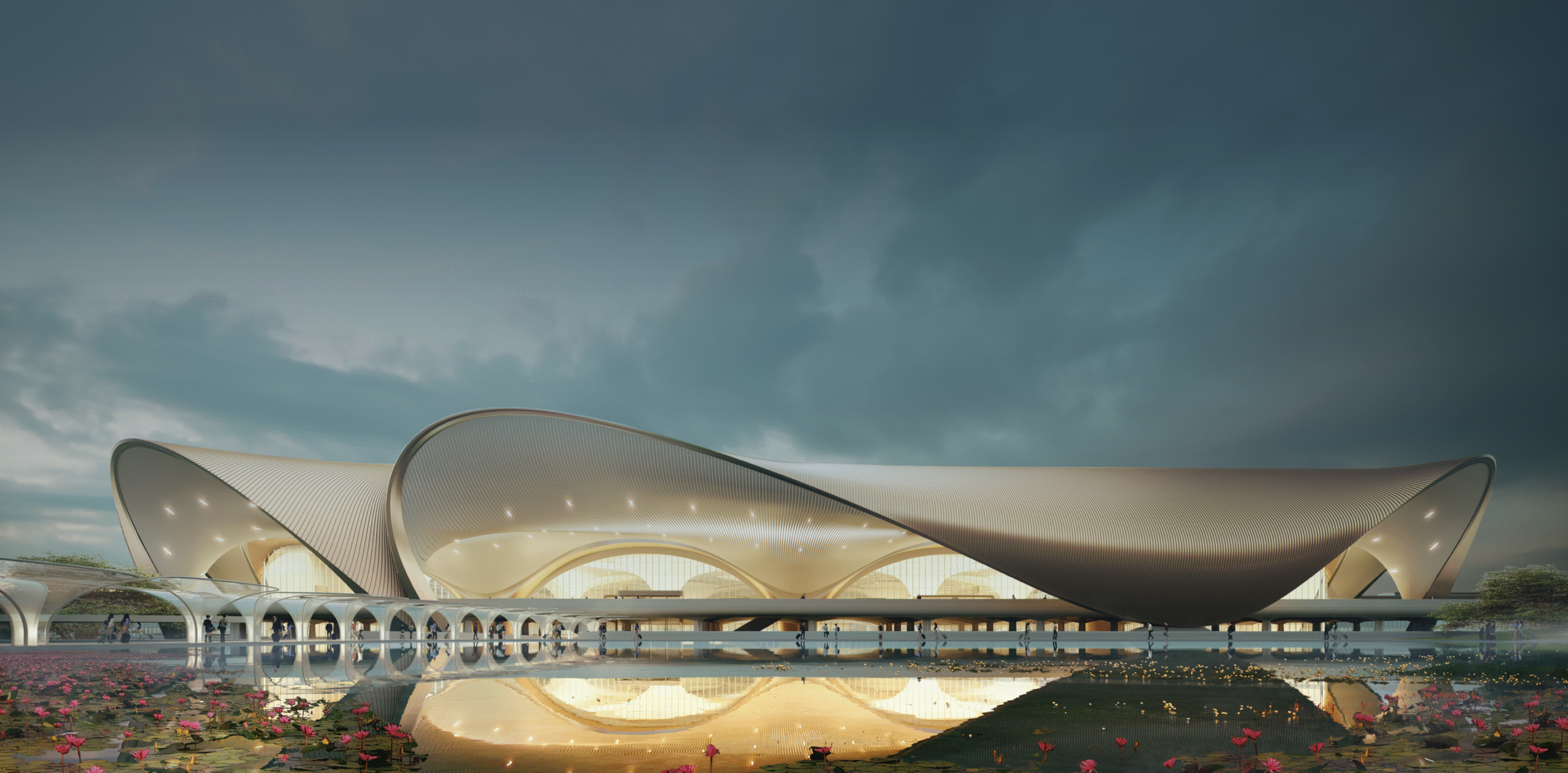

Above: The pavilion, 3D printed using twine and rock aggregate, is part of an exhibition on robotics at Wintherthur's museum (image courtesy of Michael Lio).

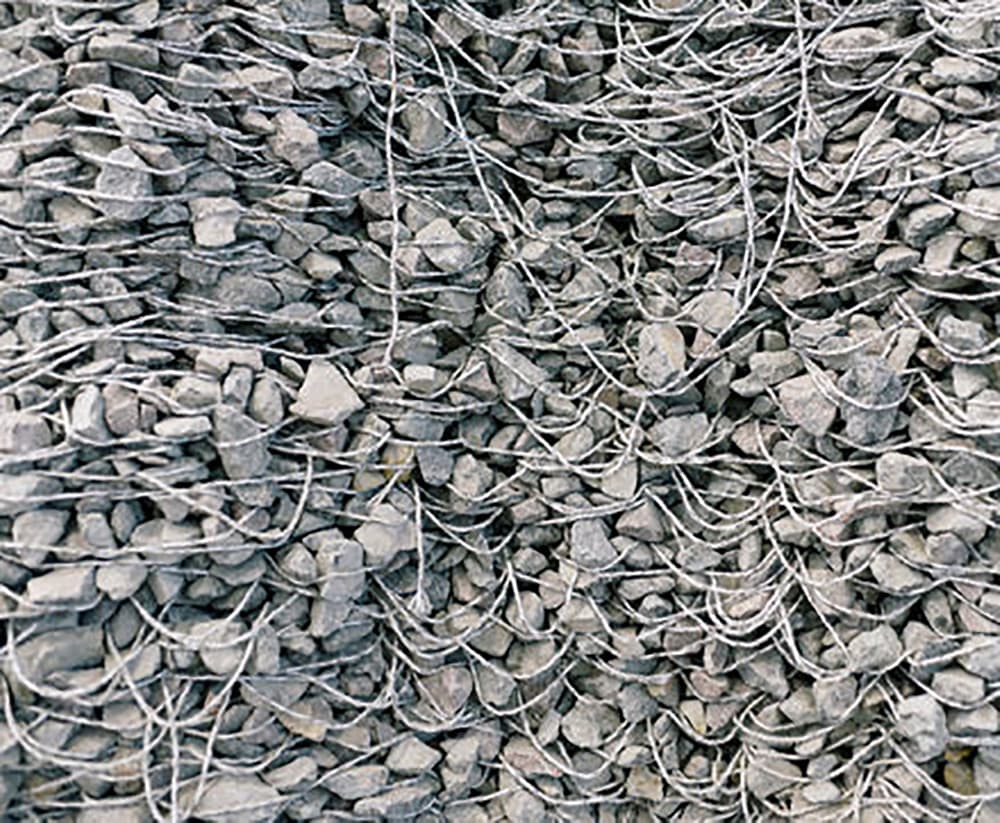

Called "Rock Print", the technique was first showcased in Chicago in 2015 and was developed by ETH Zurich and MIT. Layers of compacted aggregate are combined with twine to help stabilise the final structure in a technique known as "jamming".

The pavilion in Winterthur features 120 kilometres of string and 30 tonnes of loose stones.

Above: The printing technique, also called jamming, includes deposition and compacting of layers of loose gravel on top of twine ( image courtesy of Michael Lio).

The pavilion consists of 11, three-meter high columns supporting an eight-tonne steel roof and took four weeks to construct.

Above: The technique was developed by researchers from ETH Zurich and MIT (image courtesy of Michael Lio).

As with previous structures made using the rock-printing technique, they can be easily disassembled into their constituent materials: the aggregate can be reused and the twine, if made of natural fibres, is biodegradable.

Above: A structure 3D printed in this way can be easily disassembled and its materials reused (image courtesy of keystone / Chritian Beutler).

Winterthur's Rock Print Pavilion is a temporary structure which will be on display for the duration of Gewerbemuseum's exhibition, ending on 4 November 2018.