Longlist Revealed: These are the Best Construction Stories of 2023

IT’S BEEN a huge year for the world's greatest industry.

We’ve been blown away by all of the amazing entries that we received for Construction Story of the Year in 2023. There’s no shortage of inspiring, boundary-pushing work that is quite literally shaping the world around us.

Traditionally the construction sector hasn't been great at shouting about itself, but we know that stories cut through more effectively than anything. So, together with Nemetschek, we set out to find construction's most impressive and inspiring stories, lifting them up and using their success as a means to promote this fantastic industry. After much-deliberation amongst our expert judges, we have arrived at the longlist.

From this we’ll select three finalists and reveal them in three short video features at the beginning of October. We’ll then pull together feedback from you, our audience, and our judges’ final thoughts to arrive at an overall winner, set to be announced on 16 November.

P.S. Entries are not listed in any particular order!

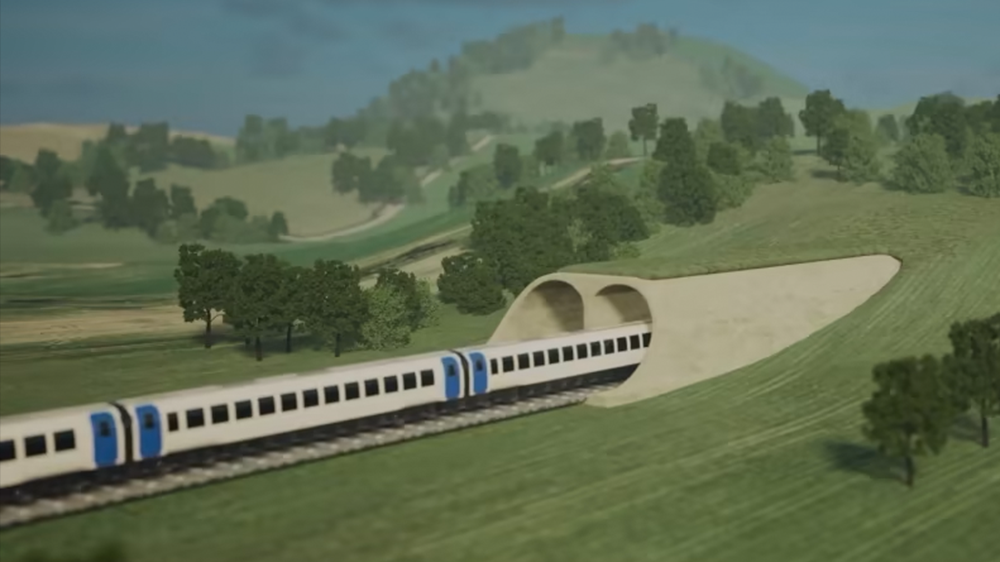

Above: The Copthall Tunnel will be integrated into the surrounding environment. Image courtesy of HS2.

Copthall Tunnel, HS2

A green tunnel within the UK’s most complex infrastructure project.

High Speed 2 – or HS2 as it’s better known – is one of the largest construction projects the UK has ever undertaken. One of the many incredible feats of engineering involved is the Copthall Tunnel, an 880-metre reinforced concrete tunnel that's being built using the cut and cover method.

It’ll be one of five so-called “green tunnels” along the route which are shallower than usual and will be covered with trees and shrubbery.

To make that possible, a whopping 500,000m3 of excavation works is being carried out, and much of that excavated material is being kept on site and reused on the tunnel surroundings. That means less spoil needs to be moved around by truck, and that the finished tunnel will largely blend in with the natural environment.

What’s really unique is how this element of the project is using the latest breakthroughs in AI to turbo charge its digital capabilities. Skanska Costain Strabag (SCS) Joint Venture's Copthall Tunnel Team, led by Ray Moloney, teamed-up with ALICE Technologies to combine metadata from their building information model with the generative scheduling features in ALICE.

By linking parametric data to the schedule, the team were able to create highly engaging and easy-to-grasp visual 4D model sequences of the works. They could then test and explore different build scenarios digitally, arriving at the optimal solution before starting works for real on site.

The approach enabled them to win back 5 weeks on a key project milestone.

Above: The Mont Cenis Base Tunnel goes through the Alps. Image courtesy of TELT.

Mont Cenis Base Tunnel, Lyon-Turin Railway

The world’s longest rail tunnel through the Alps.

Construction projects don't get much more epic (or daunting) than this. Led by TELT, France and Italy are building a massive new 270-kilometre railway between Lyon and Turin, tunnelling deep beneath Europe’s largest mountain range.

This astounding scheme is just part of one of the continent’s most critical infrastructure schemes – the TEN-T transport network. When finished, the railway will offer a new low-carbon link between Western and Central-Eastern Europe, slashing journey times and delivering numerous economic benefits.

To complete the central link of the Mediterranean Corridor, the 57-kilometre Mont Cenis Base Tunnel is being built straight through the middle of the Alps.

With varying ground conditions and work at extreme depths, it's undoubtedly the most challenging part of the project. Planned, co-ordinated and led by the teams at TELT, the tunnel will become the world’s longest rail tunnel once it completes.

This amazing team is now well on its way to creating a more interconnected Europe.

Above: The Chicago Tribune Tower has been restored and redeveloped. Image courtesy of Tribune Tower West (Chicago) Owner LLC.

Chicago Tribune Tower

An iconic building restoration.

One of Chicago’s most legendary landmarks just got the upgrade of a lifetime. From 1925 to 2018 this 34-storey neo-gothic office tower stood as the home of the Chicago Tribune newspaper. But when the paper moved out, the historic building was preserved, restored and developed into 162 condos.

The project was led by Chicago-based architects Solomon Cordwell Buenz on behalf of developers CIM Group and Golub and Company.

Construction crews worked meticulously with historians to repair the limestone facade, leaving most of the exterior unchanged from its original state. They also preserved the tower lobby and ironwork on the elevators. It’s a stunning example of how historic architecture can be blended with modern amenities without sacrificing the building’s character.

As cities around the world face a growing stock of empty offices, calls are growing stronger to repurpose the underutilised space into something new like housing. Projects like this set an example of how conversions can be carried out, while still allowing the original tower’s legacy to live on in a new way.

Above: London's Cody Dock Bridge rolls without any electricity. Image courtesy of Thomas Randall-Page.

Cody Dock Bridge

A mesmerising rolling bridge in London.

If you build a bridge over a boat’s path, typically you’d engineer it so that it can raise up and above the vessel as it passes through. But this is not a typical bridge. Designed by Thomas Randall-Page, the impressive and innovative new structure down at East London's ex-industrial Cody Dock is a 13 tonne square-shaped rotating footbridge.

Made of weathering steel and oak, the bridge’s modern design makes use of Victorian industrial mechanisms. It doesn’t require any power to rotate, just a series of hand cranks that move the bridge’s steel gear teeth along a track on the channel.

Not only is this one of the most innovative bridge’s we've come across – it’s also super satisfying to watch.

Above: The Northwest Outfall team came up with a new solution for sewerage problems. Image courtesy of Northwest Pipe Company.

The Northwest Outfall Project

An innovative approach to sewage issues in Arizona.

This project really makes you realise the hidden power of construction. If you’re just walking down the street, you probably wouldn’t notice how great the sewage system is. But you would notice when it’s not working so great.

Tucson, Arizona developed a bit of an odour problem.

The Northwest Outfall Siphon is a dual-barrel sewer siphon under the Santa Cruz River. The way the system was functioning meant that raw sewage was corroding the existing tunnels and releasing aggressive odours. So the rehabilitation team engineered two new, corrosion-resistant fibreglass-lined structures to stop the flow churning and releasing corrosive gases. But in order to replace the original tunnels, they had to find a way to safely move 15 million gallons per day of raw sewage across the river.

Drilling deep under the river wasn’t an option due to regulations, so they had to go over it. Instead of building a costly bridge, a team of contractors designed, erected and removed a single-span temporary bridge – saving the environment and the community a whole lot of trouble.

The Northwest Outfall Team consists of Hunter Contracting, the Pima County Wastewater Reclamation Department and Dibble Engineering.

Above: Chicago's Tunnel and Reservoir Plan is decades in the making. Image courtesy of Metropolitan Water Reclamation District of Greater Chicago.

The Tunnel and Reservoir Plan

A secret tunnel network under Chicago.

Some of construction's most fascinating and impactful projects really do happen out of sight and out of mind for most of the population.

Deep beneath the city of Chicago lies a sprawling 175-kilometre network of tunnels designed to protect the area’s waterways. The Tunnel and Reservoir Plan – or TARP – is part of one of the largest civil engineering projects in the world.

The huge project is managed and being constructed under the Metropolitan Water Reclamation District of Greater Chicago. It’s meant to help manage the overflow and pollution issue. Any extra runoff water from storms could now be redirected through the new tunnels and stored in the reservoirs before being treated and eventually released.

After decades of work and billions of dollars in funding, sections of the plan are finally starting to open. As we start to build the next generation of infrastructure projects, TARP can serve as an example for other cities’ who need to address flooding.

Above: HAUT a new mass timber building in Amsterdam. Image courtesy of Jannes Linders via Team V.

HAUT Amsterdam

One of the world’s tallest mass timber towers.

Mass timber construction just keeps getting bigger, and Amsterdam is now home to one of the tallest timber buildings in the world. Designed by Team V Architecture and constructed by JP van Eesteren, HAUT is a 73-metre residential tower containing 52 apartments constructed primarily from wood.

Right now, the construction industry and the built environment is responsible for about 40% of global CO2 emissions, largely due to the use of materials like concrete and steel. Mass timber is a much lower-carbon alternative when sourced from sustainably managed forests.

HAUT was built with sustainability in mind throughout the entire design. The roof and facade are fitted with solar panels, cooling is sourced from the ground, there are nesting boxes for birds and bats, shared charging points for electric cars and a rooftop garden with rainwater storage.

Above: Facade work on the US Capitol Building is a high-pressure act.

US Capitol Building

Innovative scaffolding on one of America’s most visible landmarks.

Putting up scaffolding around any building is no small task. But the US Capitol Building? Now that’s a tall order.

The American landmark isn’t actually made of stone: it’s painted. That means every 15 years it needs a touch up. And that means a lot of scaffolding has to go up over an extremely visible, busy, high-security site.

If all of that weren’t enough pressure, most of that work had to be done between 22:00 and 06:00 so as to not disturb the daily operations. Each construction team member had to go through security checks, which made any changes to the crew a complex undertaking.

The inspiring team at Maryland-based Scaffold Resource stepped-up to the task and even became the first US company to use KEWAZO'S material-lifting LIFTBOT on site.

The brave and innovative application of this technology in what is a traditionally conservative field helped to supplement manpower and improve operational efficiency by 50%, lower the risk of objects falling and create a safer jobsite. The project stands as a case study for more efficient and safer scaffolding projects in the future.

Above: This resort sets out to make Brisbane an international travel destination. Image courtesy of DBM Vircon.

Queen’s Wharf Brisbane

A world-class resort in Australia’s fastest growing city.

Construction projects rarely get more complex or collaborative than this.

Some quick context for you: Brisbane is in the middle of a transformation. The city is growing at a staggering rate, and is preparing for a huge influx of visitors when it hosts the 2032 Summer Olympic Games.

At the heart of the city’s central business district (CBD) is Queen’s Wharf Brisbane, a new $3.6BN development on the river’s edge that's now the largest precinct development in the Southern Hemisphere.

Stretching across more than 26 hectares of land and water, this massive development makes up 10% of Brisbane’s entire CBD. It’ll contain 50 bars, cafes and restaurants, 1,500 new apartments, more than 1,000 hotel rooms, a casino, nine fully restored heritage buildings and 7.5 hectares of public space.

To plan, co-ordinate and deliver this complex scheme, DBM Vircon established Brisbane's Digital Engineering Team led by Nick Rostin and Gabor Gulyas.

They embraced an Open BIM workflow and employed 16 different pieces of digital construction software, putting them to use across some 50+ contributing organisations. By working in a building information modelling (BIM) environment and creating a central common data environment for all to access, the team was able to cut the time reviewing drawings by 50%, streamline collaboration and significantly enhance stakeholder engagement. Co-ordination was transformed as each trade and specialist was able to better see and understand its element of the works and how it interfaced with others.

The data produced in the information model will also go on to be used in the development's lifecycle asset management.

DBM Vircon's work at Queen's Wharf is testament to the benefits of Open BIM and the power of digital construction technology on major projects.

When the new district opens in April 2024 it should help put this city on the map as an international destination.

Above: The Bay Area's public transit got a seismic retrofit. Image courtesy of BKF Engineers.

Bay Area Rapid Transit District

A seismic retrofit of California’s public transit.

The Bay Area’s public transit system got a huge upgrade – and most of its 400,000 daily riders probably didn’t even realise. Originally constructed in the 1960s and 70s, The Bay Area Rapid Transit District (BART) TransBay Tube (TBT) is an incredible feat of engineering, stretching 5 miles long to connect San Francisco with Oakland.

The tube is made up of 54 individual segments that were constructed on land, sealed with steel bulkheads, floated into the bay, sunk, welded together, and then covered with a thin layer of the native bay floor.

But some time has passed since it was first built and it was due for a seismic retrofit.

The special projects, construction staking and reality capture team at BKF Engineers stepped-up to the plate. Construction teams could only work between 01:00 and 03:45 in the morning when the service was shut down. With such tight constraints, BKF Engineers embraced digital construction technologies and data - laser scanning and modelling the track and tunnel to with 1/16" tolerance ensuring they knew exactly what they had to do before heading to site and that none of their new installations would collide with the 80mph trains passing through.

These amazing crews successfully navigated tight spaces, limited access and electrical hazards to upgrade the structure, making the trains safer for everyone.

Above: New residential housing in Canning Town East London. Image courtesy of Morgan Sindall Construction.

300 Manor Road

A digitally-advanced East London residential project.

East London is getting a new cluster of residential towers that are set to provide more than 800 sustainable homes, half of which will be dedicated to affordable housing.

The buildings will make use of vegetated blue roofs that capture stormwater run-off and the development will have space for new businesses alongside a new 2.9 acre park.

But building all of that was far from easy. There were more than 50,000 individual construction activities, and the site had several limitations which made it difficult for crews to stay on the same page.

Construction tech-firm Sablono teamed-up with Morgan Sindall and deployed a digital project management tool that helped take control of the project: from data insights and visual tracking of complex elements through to real-time tracking and lean planning.

As a result, the team has been able to save more than 10,000 hours of time across documentation, inspections and weekly meetings.

Above: Poland's new administrative office contains a passive building. Image courtesy of Mostostal Warszawa.

West Pomeranian Voivodeship Marshal's Office

An eco-friendly restoration project in Poland.

What was once an uninhabited building is now being transformed into a sustainable public administration office in Poland. The project is both reconstructing an old building and constructing a new connected “passive” building.

Now, to be considered a passive building, it needs to be designed in a way that requires very little energy usage.

Embracing an Open BIM approach from the outset, the Mostostal Warszawa Site Management Team undertook a complex deep renovation and thermo-modernisation to make this possible, earning BREEAM Very Good certificates and a Certification from the Passive House Institute in Darmstadt.

This team pushed the boundaries of digitisation in construction, providing more than 300 people with access to structured digital information, reducing costs and improving efficiency while helping setting a new standard within the organisations involved for future projects to come. By collating data from many points - including laser scans, point clouds and 360 photos - real-time progress could be tracked against the design model., and the use of IFC models streamlined digital collaboration between organisations.

This long-term digital approach greatly eased the transfer of data from the construction through handover and onto the building operation phase.