What is "Scan to BIM"?

- Youtube Views 133,449 VIDEO VIEWS

WHEN people say “scan-to-BIM” they are referring to the process of “3D laser scanning” a physical space or site, to create an accurate digital representation of it. That representation can then be used for designing, assessing progress or evaluating options.

That’s it in a nutshell. But of course that nutshell is not exactly easy to get your head around.

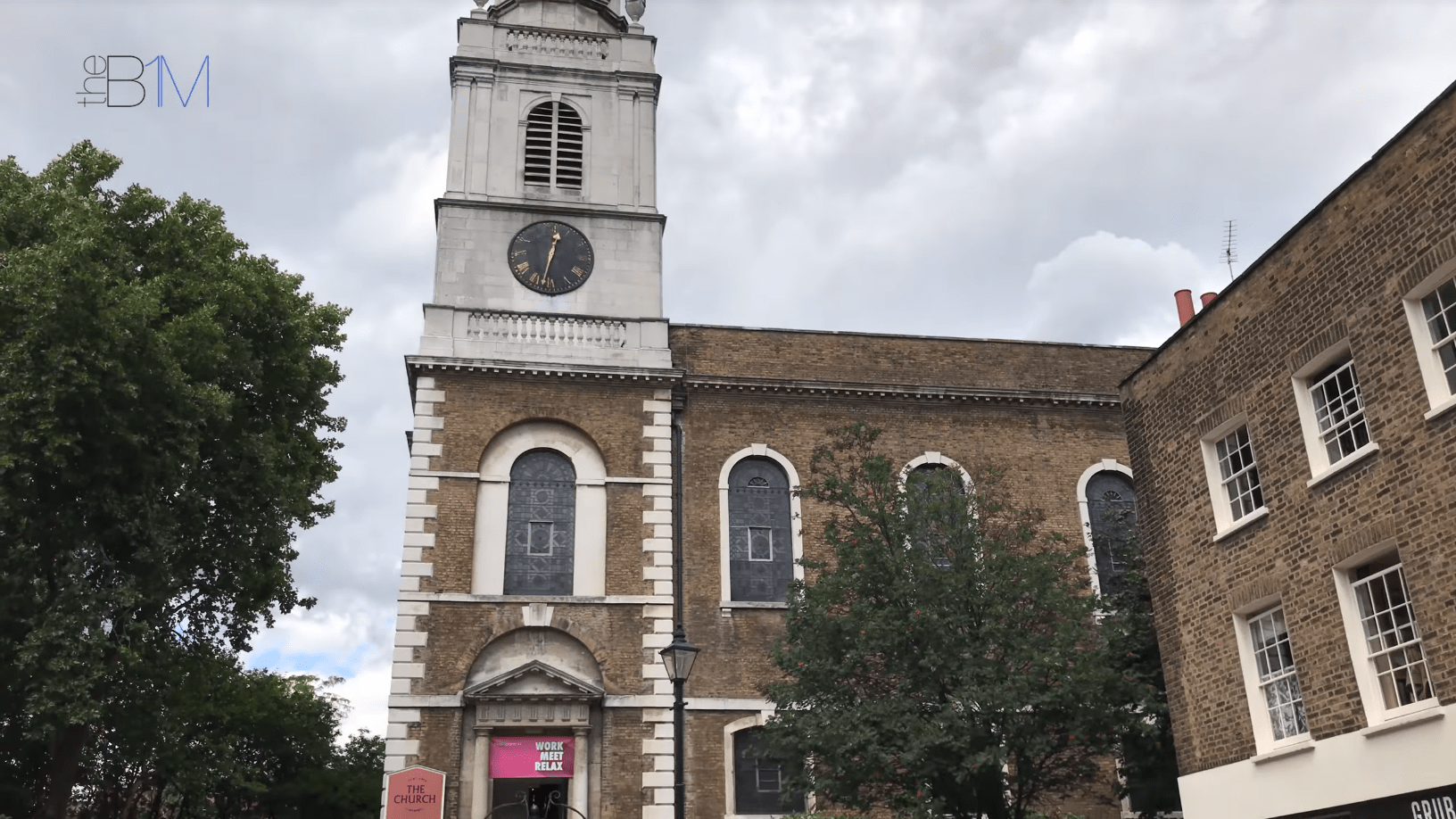

To help, The B1M commissioned a 3D laser scan of a heritage building – London’s beautiful St James’ Church – and created this step-by-step explanatory video, demonstrating how the process works and the benefits it can bring.

Firstly it is important to determine why you wish to create a digital representation of a space and to be clear about what you will use that data for. If the team you commission to undertake your survey know what it needs to be relied upon for, they can ensure you receive a scan that best meets your needs.

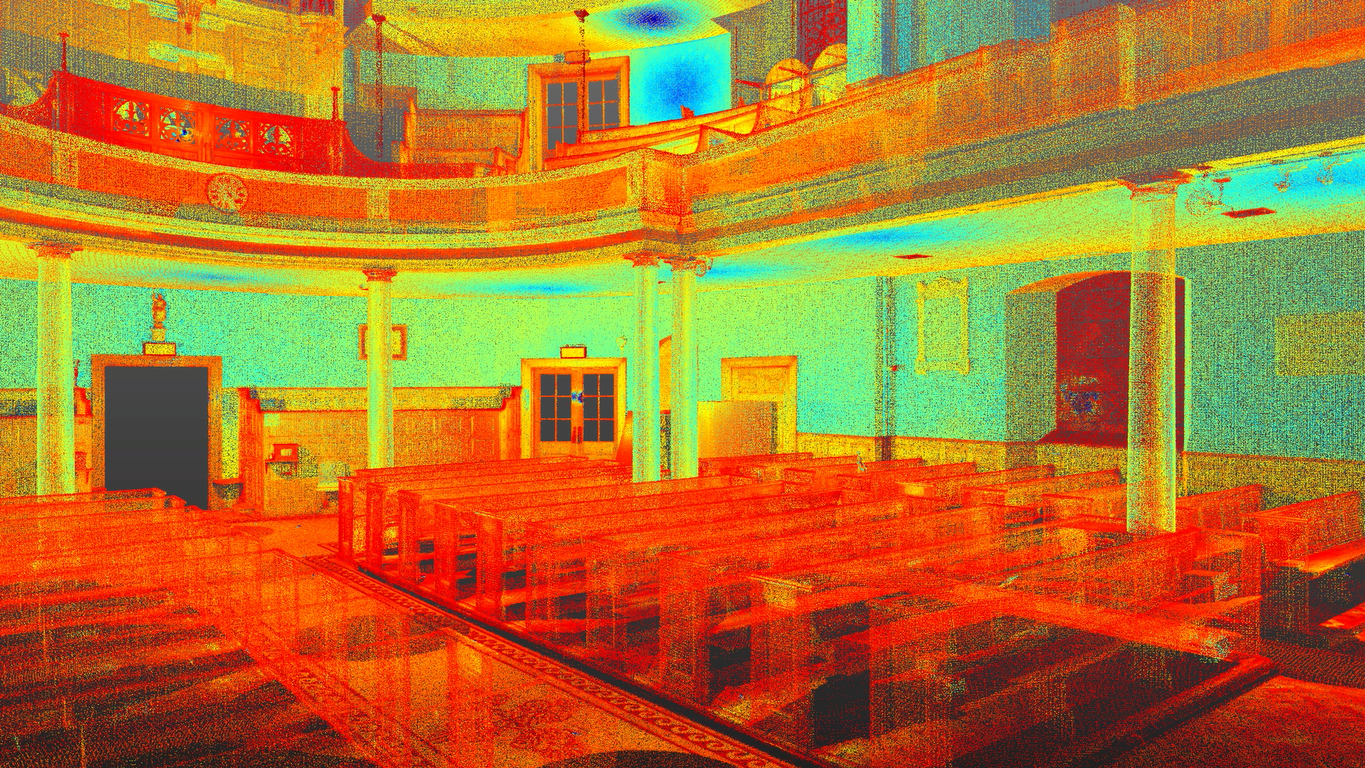

Above: The B1M commissioned a 3D laser scan of St James' Church in Clerkenwell, London.

The scanning process can in theory be undertaken by just one person, though this is dependent on your site and the outcome a thorough risk assessment.

Using a standard tripod, a 3D laser scanner is attached. Scanners like the Trimble TX8 (demonstrated in this video) are reasonably lightweight and come in easily portable cases.

Above: The Trimble TX8 in its portable case, and Below: The TX8 mounted on a tripod in St James' Church.

Before a scan commences, some key parameters need to be entered into the scanner’s touch screen interface (pictured above), but we will explain more about

these later on.

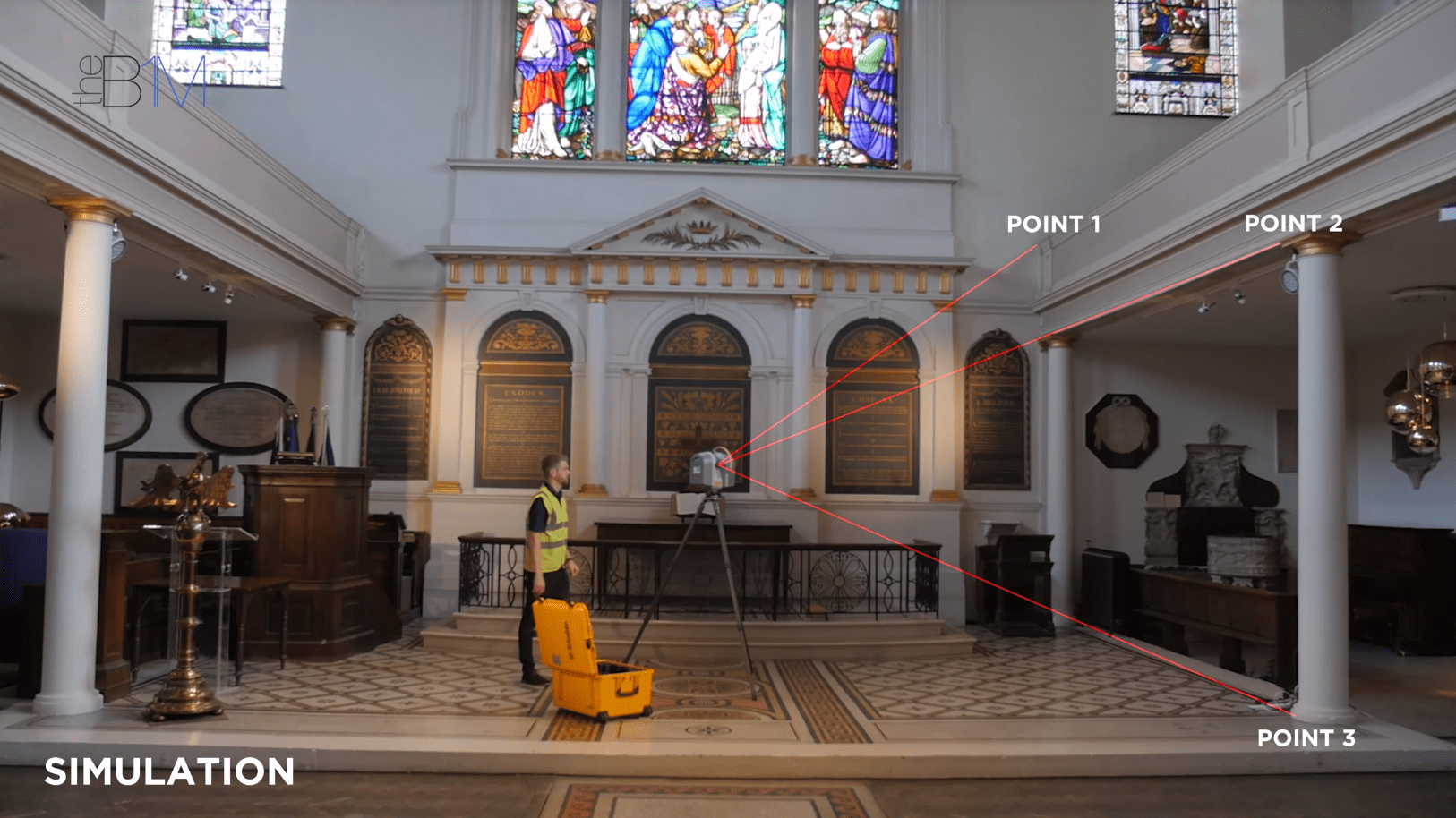

To capture a digital representation of a space, a laser within the scanner case rotates at high speed. As the invisible laser beam hits various objects or materials, their position relative to the scanner and to other elements of your site or building is recorded as a piece of digital data. This is known as a “point”.

When several of these points are collected they begin to build a highly accurate three-dimensional digital picture of the space or site being scanned. A large collection of these points is commonly referred to as “point cloud”.

The more points that you collect, the greater the accuracy of your scan – a factor commonly referred to as a scan’s “resolution”. There will be times when you need the highest possible scan resolution, but this is isn’t always necessary and it comes back to determining what you want to use the scan data for, right from the outset.

Above: An annotated simulation of the 3D laser scan in progress, showing data being collected on a range of points.

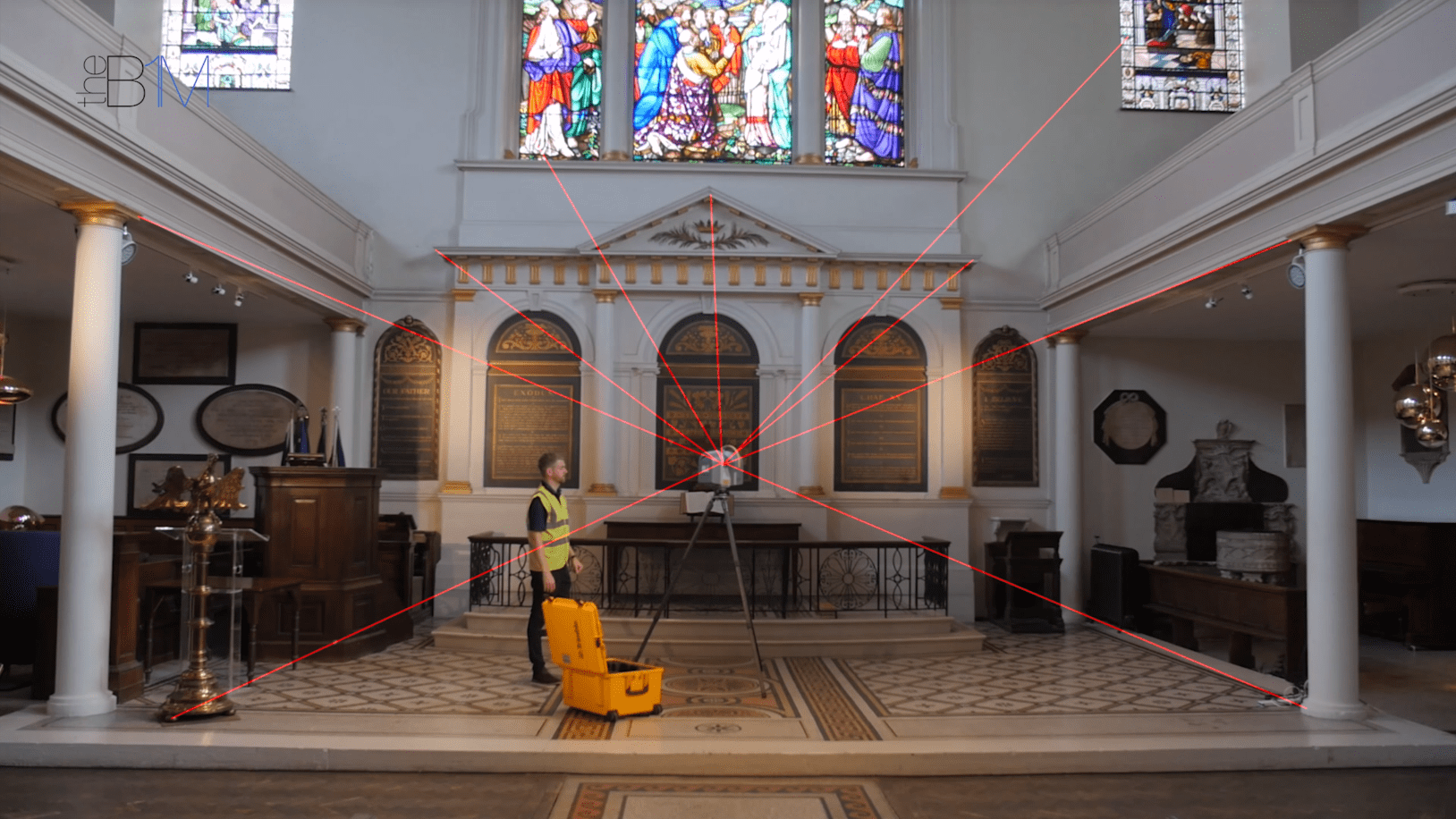

The scanner automatically rotates during the scan process to capture the area being scanned. It may perform a complete 360 degree rotation or a lesser turn, depending on the data to be captured. The Trimble TX8 can reach points up to 340 metres away with its extended range.

The scan area and your desired resolution are all entered as part of that parameter data we mentioned earlier on.

To give you some idea of the magnitude of data collected during a typical 3D laser scan, the Trimble TX8 collects data on one million unique points every second. That’s around 300 million points during a five minute scan.

3D laser scanning removes a large degree human error from the surveying process and enables significantly higher volumes of data to be collected over a considerably shorter period of time. This means that survey information can be relayed to project teams faster. It also enables Surveyors to undertake more scans than they could have done previously.

"The Trimble TX8 collects data on one million unique points every second. That’s around 300 million points during a five minute scan"

The lasers used within 3D scanners are of no risk to people or animals and cannot materially affect or damage a building’s fabric. This is a particularly important consideration when working with heritage schemes, like the one shown in this video.

A high resolution camera on the front of the Trimble TX8 scanner captures images of the scan area, simultaneously to the laser scan. This enables the scan data to be “colourised” at a later stage, creating a realistic render.

The laser beam emitted by the scanner can only travel in a straight-line from the spot where the scanner is positioned. Therefore, to build a complete digital representation of a site or building, multiple scans will need to be taken from a variety of locations, ensuring complete coverage of the space.

This is another reason why it is important to determine the objectives your laser scan from the outset. You don’t want to scan more areas than are necessary.

Above: As the laser beam emitted by the scanner can only travel in a straight-line, multiple scans may be needed to ensure complete coverage of the site or space.

So that’s the scanning part, but how do you bring that digital data that you have collected out in the field, back into the office for use by a project

team, potentially in a building information modelling (BIM) environment?

With your scan complete, the data captured can be taken out of the scanner on a simple USB drive. You can then insert that into a standard USB port on your computer device.

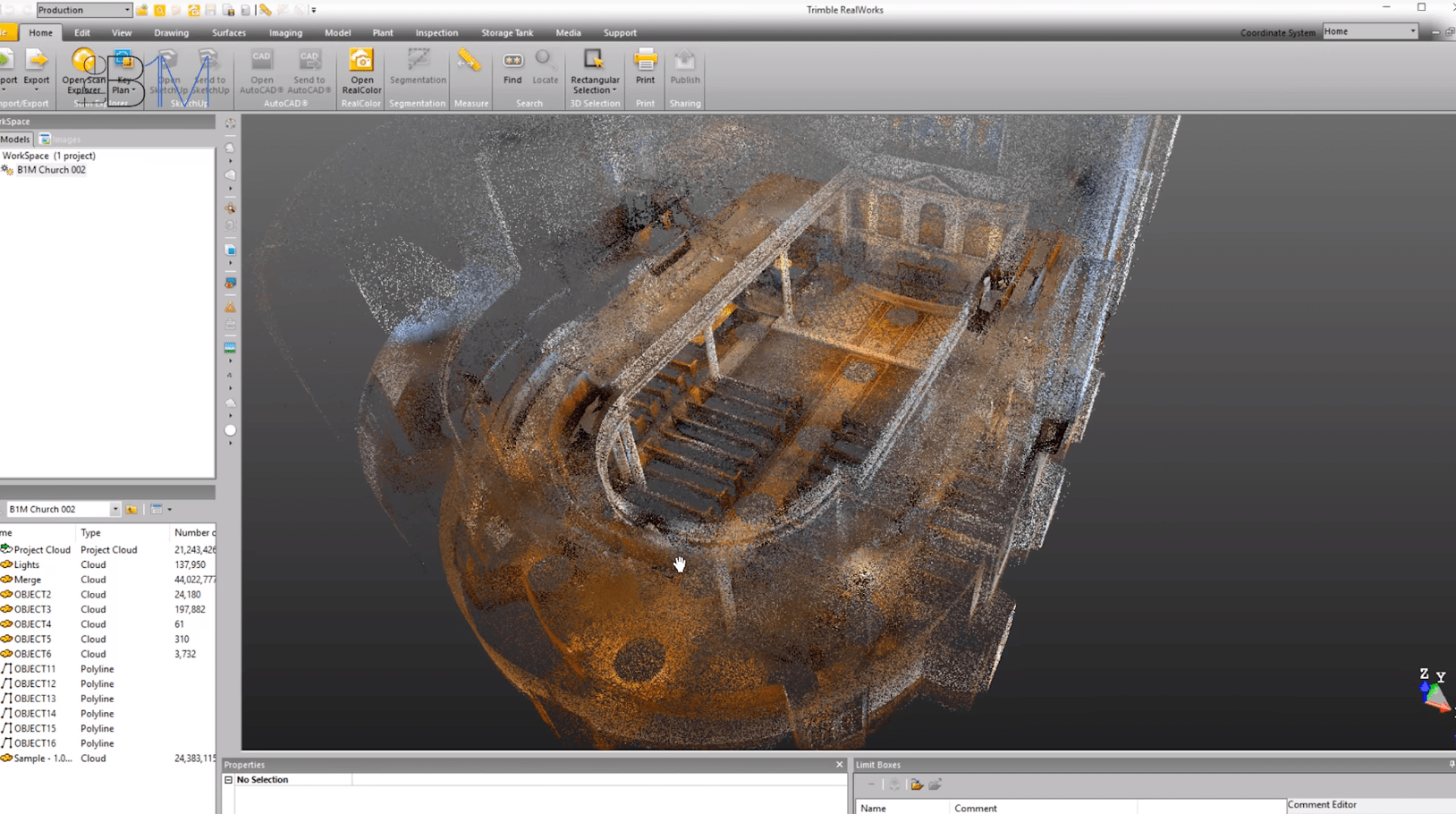

What happens next depends to an extent on the scanning hardware you used, but for most scanners you will need to open the raw scan data in a software programme that calibrates it before it is ready for sharing with others or for importing into design authoring programmes or into your project’s common data environment.

Having scanned with Trimble’s TX8 in this video, we have import our scan into Trimble RealWorks; a powerful software tool that enables you to register, analyse and model from your scan. The platform has a free browser-based viewer enabling your wider project team to see and navigate around your scan.

Above: The St James' Church scan in Trimble RealWorks.

The process of importing and calibrating raw scan data before its ready for use by a project team is quite specialist and it is advisable to commission your Surveyor (the person who undertook your scan) or a qualified party to undertake this process. We demonstrate the step in this video to better explain how the complete process works.

Having a highly accurate three-dimensional digital representation of your building or site available – in record time – is very powerful. You are now more informed to develop your design proposals, scope out your works or to verify the progress of works to date. Those engaged with asset management quickly have a picture of their existing stock to hand.

Above and Below: The results of the St James' Church scan.

Above: Accurate measurements being taken from the three-dimensional scan in Trimble RealWorks.

Beyond the construction industry, 3D laser scanning has many other applications, including for example in forensics; where it is used to quickly and accurately document crime and accident scenes before such areas are re-opened to traffic or the public.

This video contains product placement by Trimble MEP. Our thanks to St James’ Church, Clerkenwell. We welcome you sharing our content to inspire others, but please be nice and play by our rules.