What is 4D Printing?

- Youtube Views 95,931 VIDEO VIEWS

4D PRINTING refers to 3D printed objects that have the ability to reshape or self-assemble over time. The concept was born out of the Self-Assembly Lab established by Skylar Tibbits at the Massachusetts Institute of Technology (MIT) under research supported by Stratasys and Autodesk.

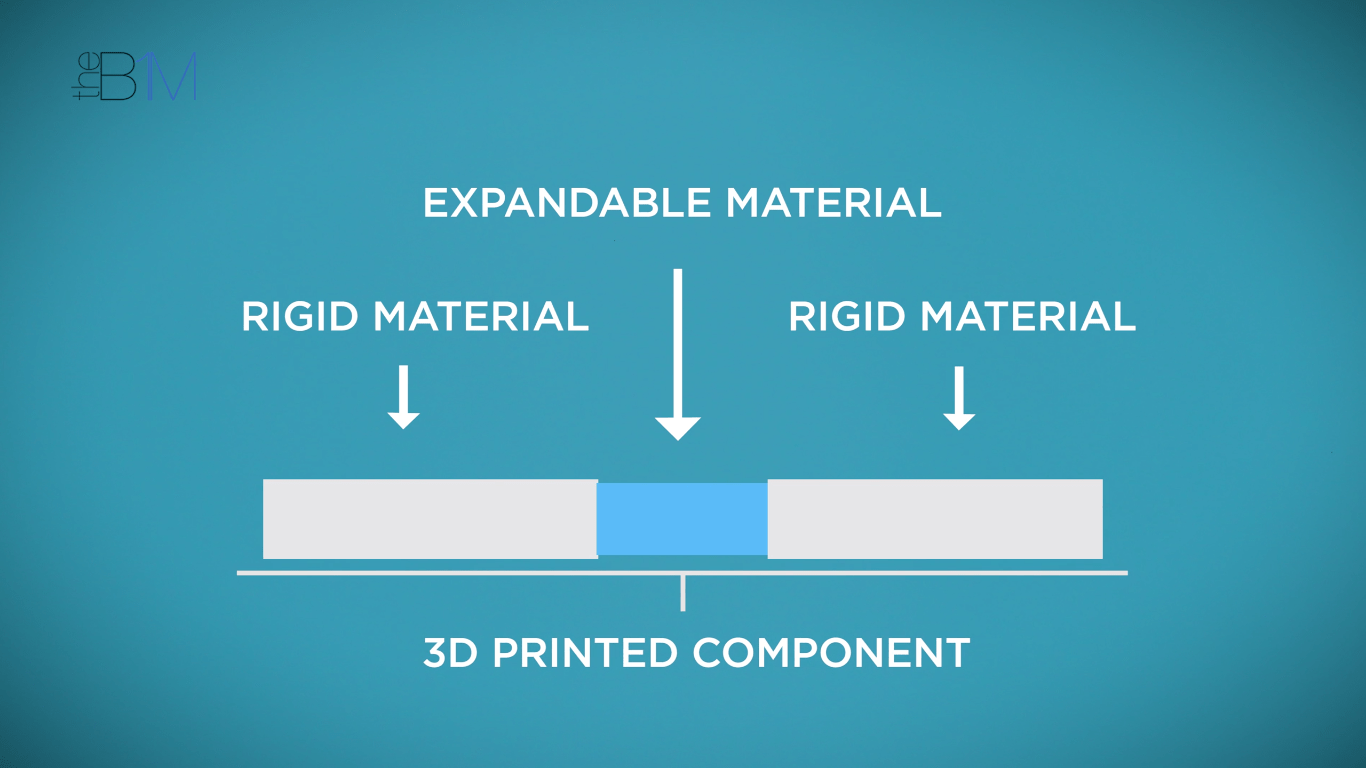

It involves strategically positioning rigid and expandable materials next to each other within one 3D printed component. When the expandable materials come into contact with water, they grow to up to 200% of their original volume, changing their shape and repositioning the rigid materials either side of them.

Above: Rigid and expandable materials positioned next to each other within a 3D printed component. Below: The expandable material grows when it comes into contact with water, re-positioning the rigid materials either side of it.

.png?Action=thumbnail&algorithm=fill_proportional&width=550)

The expandable materials effectively create ‘joints’ in the component that are activated in certain conditions, causing the entire component to adopt a

different form. Depending on the expandable material used, the contact substance necessary for it to change shape could be water, or it could be heat,

light or a range of other simple energy inputs.

Software enables the components to be programmed on-screen before they are printed and for that data to have effectively been programmed into the component once it has been created.

.jpg?Action=thumbnail&algorithm=fill_proportional&width=550)

Above: 4D printing in action at MIT's Self Assembly Lab (image courtesy of Self-Assembly Lab / MIT, Stratasys and Autodesk).

Going beyond the range of small-scale demonstration pieces created to date,

it’s thought the technology could be used in some form of self-repairing water pipes, in pipework that changes size in relation to water flow or in

hot and cold temperature water valves.

Beyond plumbing it also has potential in medicine, clothing and footwear that adapts to climatic conditions or in childcare products that respond to temperature changes.

WATCH NEXT: WHAT ARE "SMOG-EATING" BUILDINGS?

Images and footage courtesy of Massachusetts Institute of Technology (MIT), Self-Assembly Lab (at MIT), Stratasys, Autodesk, University of Wollongong, Christophe Guberan and Carlo Clopath.

We welcome you sharing our content to inspire others, but please be nice and play by our rules.

.png?updated=1582727043

)