What are Horizontal Elevators?

- Youtube Views 93,410 VIDEO VIEWS

THE recently unveiled “elevator of the future” can not only travel up and down, but also sideways and even diagonally.

Created by German industrial-giant ThyssenKrupp, the world's first “rope-free elevator” looks set to create a revolutionary step-change in the design of skyscrapers, enabling them to be built even higher.

For the past 160 years, elevator technology has not evolved dramatically. Even today – whilst finishes, mechanics, travel speeds and safety measures are all more advanced – cabins are still pulled and lowered vertically by steel cables.

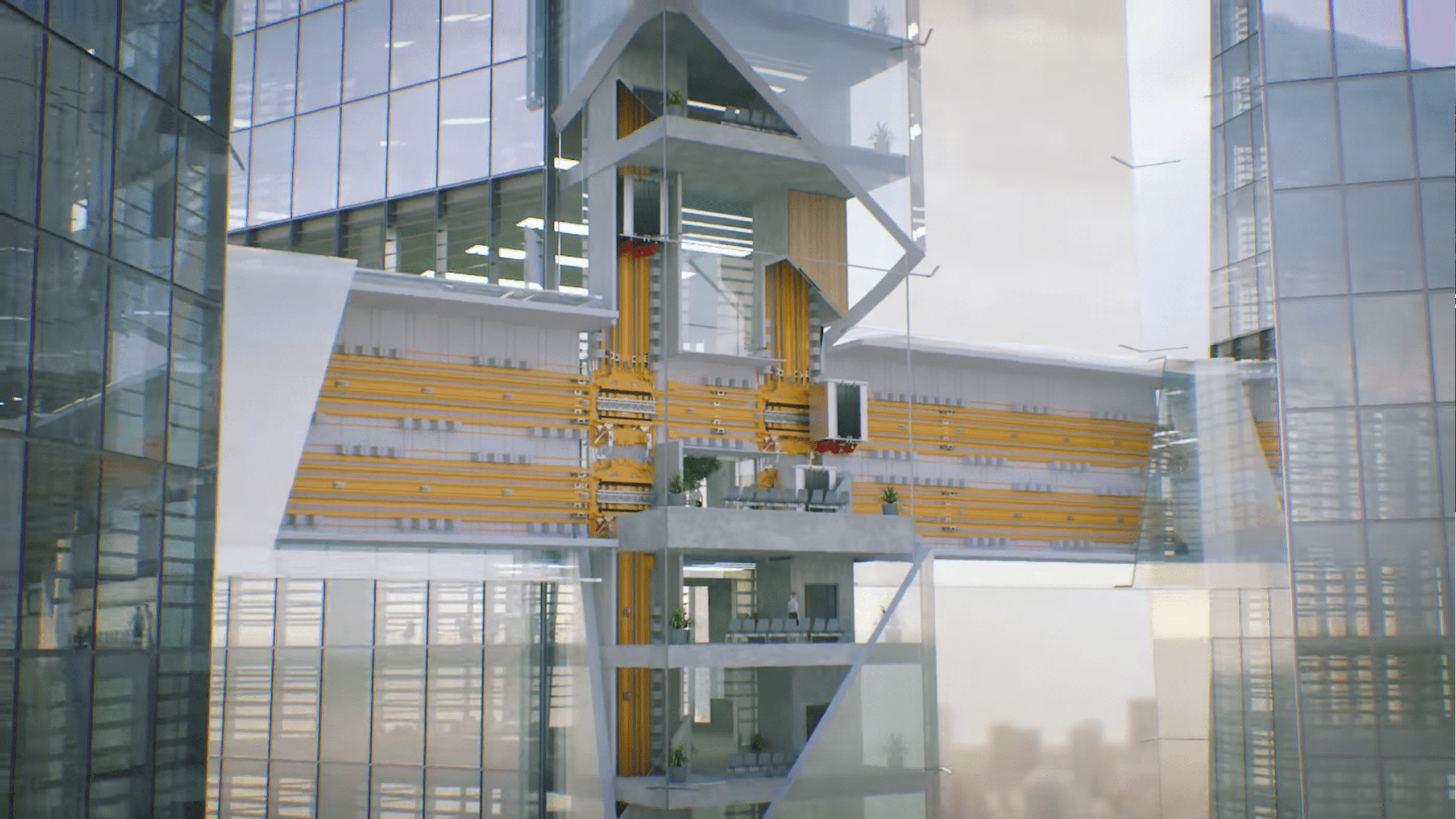

Above: The lift can operate horizontally as well as vertically (image courtesy of ThyssenKrupp).

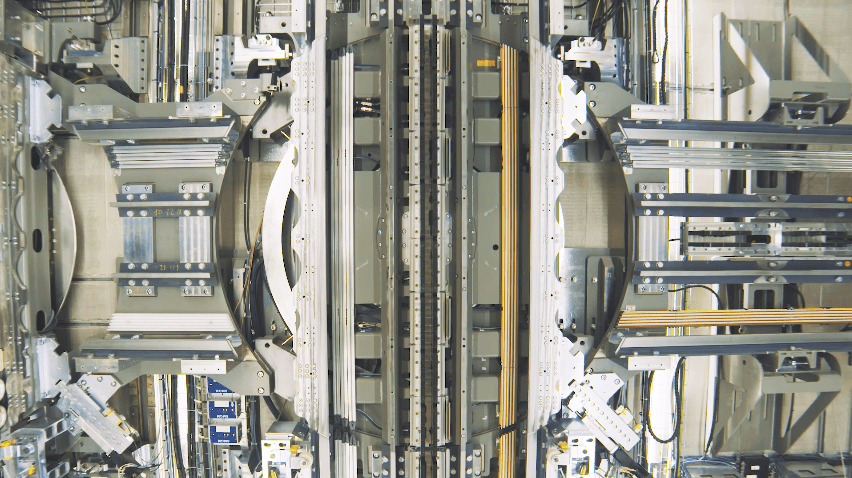

By contrast horizontal elevators have no cables. Their rope-less systems use linear motor technology developed for magnetic levitation trains. Running on tracks, cabins move in the same way that trains travel in rail systems with numerous cabins traveling up one shaft and down another in a single continuous loop.

Above: The rope less lift operates on tracks (image courtesy of ThyssenKrupp).

This approach gives horizontal elevator systems numerous advantages over traditional lifts; most notably in that they can transport up to 50% more people in a single shaft.

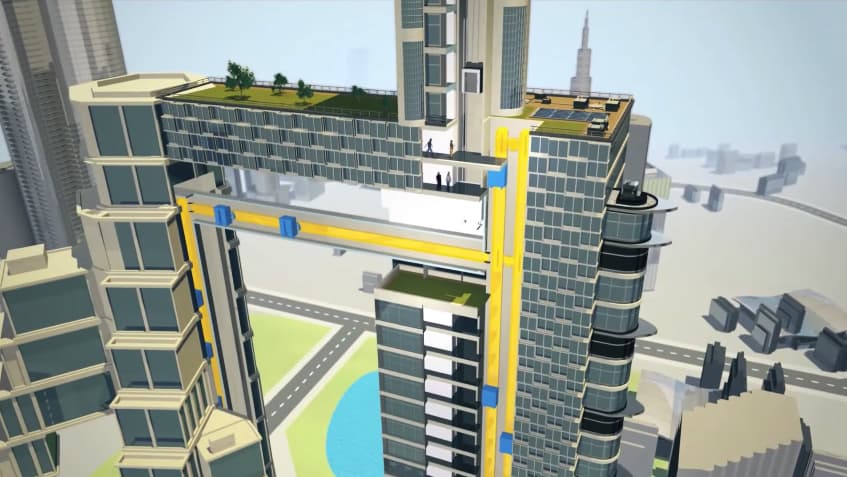

With current technology, elevator footprints can occupy up to 40% of a high-rise building’s floor space. This problem only becomes compounded in taller buildings that require more elevators. With fewer and smaller shafts, horizontal elevator systems can increase a building’s usable floor area by up to 25%, significantly improving the commercial viability of taller structures.

ThyssenKrupp also claim that their system is more efficient and environmentally friendly as compared to traditional elevators.

Above: The horizontal lift could prompt a new wave of interesting shaped skyscrapers (image courtesy of ThyssenKrupp).

Perhaps most excitingly, horizontal systems mean that vertical as well as horizontal movement is possible within buildings. This could prompt a new wave of interesting shaped structures, freed from the constraints of traditional elevator physics.

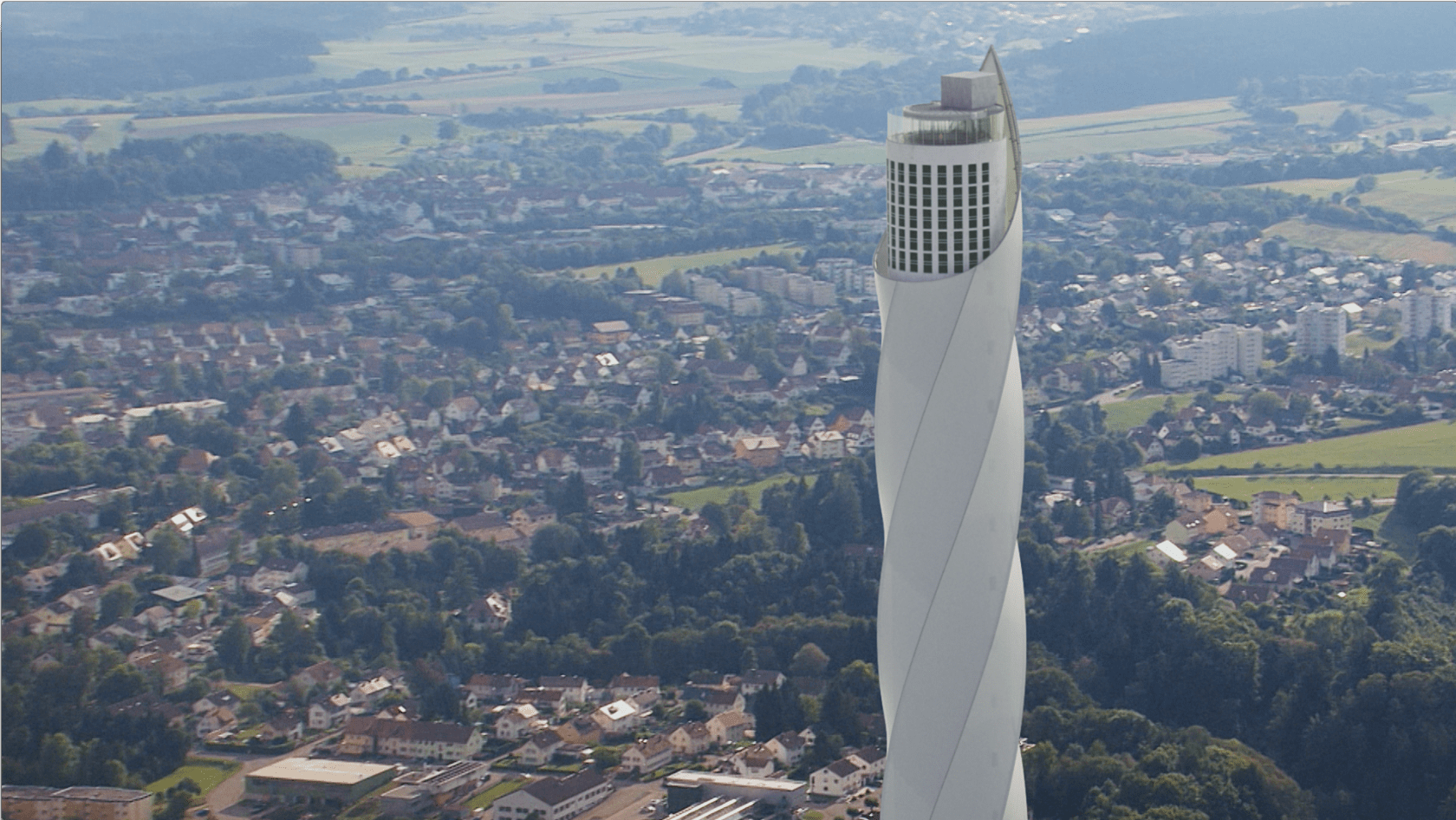

While this may all sound a little far-fetched, ThyssenKrupp recently unveiled a functioning prototype at their innovation tower in Rottweil, Germany.

The 246-meter building houses 12 shafts where engineers are currently testing the new elevators. The first live application of this technology is also on the horizon, with it set to be installed at OVG Real Estate’s “East Side Tower” in Berlin in 2020.

Above: ThyssenKrupp have developed a fully functioning prototype at their innovation tower in Rottweil, Germany (image courtesy of ThyssenKrupp).

This exciting elevator could revolutionise the way skyscrapers are designed and prompt a new generation of even higher buildings, just as the original invention of the elevator did 160 years ago. Introducing the concept, ThyssenKrupp stated that “the era of the rope-dependent elevator is now over” – and looking at the fast-paced advancement of this technology, it appears they may well be right.

This video was kindly powered by Viewpoint.

Images and footage courtesy of ThyssenKrupp. We welcome you sharing our content to inspire others, but please be nice and play by our rules.