Autonomous "TyBot" Used on Site

- Youtube Views 94,075 VIDEO VIEWS

EARLIER this year we brought you the In-Situ Fabricator; a robot developed by ETH Zurich, that could create complex, free form steel-reinforcements by cutting and welding steel rods.

Now, a promotional video has appeared featuring an admittedly more mundane, but also more battle-ready automaton: the "TyBot" - a rebar tying robot that

has made the leap from laboratory to real world application.

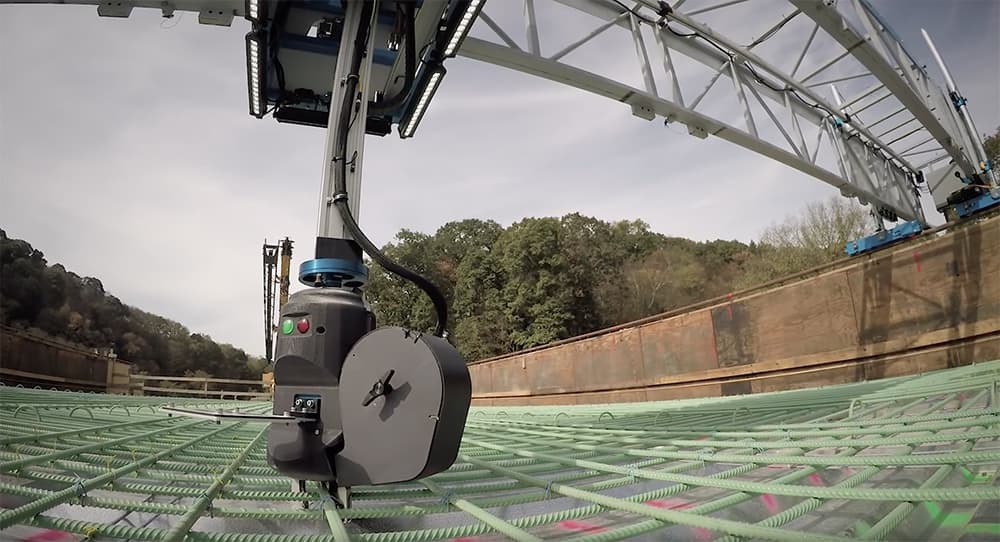

Above: TyBot, a robot designed to tie steel rebar (image courtesy of Advanced Construction Robotics).

Developed by Pittsburgh-based Advanced Construction Robotics, the TyBot has been developed to save time and reduce injuries that often arise during tying of rebar on construction sites.

Once set up, the robot works autonomously, identifying and tying intersections on its own.

Above: Tying together steel reinforcement rods can be a physically demanding and labour-intensive task (image courtesy of Advanced Construction Robotics).

So far, the Tybot has been successfully tested at Freedom Road Bridge in Beaver County, Pennsylvania. The 5,000 square feet of bridgedeck had around 24,000 rebar intersections, and TyBot took an average of 5.5 seconds tying each one.

Above: TyBot is able to work autonomously, tying each intersection in 5.5 seconds (image courtesy of Advanced Construction Robotics).

“It’s easy to integrate into current operations,” says Advanced Construction Robotics co-founder Jeremy Searock. “It only takes half a shift to assemble and fits bridges between 20 and 150 feet wide, using the existing infrastructure on a bridge project,” he continues.

Above: Bridges and other long, rectangular slabs are most suited to TyBot's current configuration (image courtesy of Advanced Construction Robotics).

So far, the gantry-type set-up means that the TyBot’s application remains limited to more rectangular and linear sites.

However, given the advances in the field of construction robotics, we should be seeing more sophisticated robots sooner rather than later.

Love construction technology? You'll love this video series.